Welding is an indispensable technique in various industries, and choosing the right welding rods is crucial for achieving strong and durable welds. Among the plethora of options available, 6010 Mild Steel Stick Welding Rods by MapleWeld stand out for their exceptional performance and versatility. In this article, we delve into the details of these welding rods, their composition, advantages, applications, and much more.

Introduction to 6010 Mild Steel Stick Welding Rods

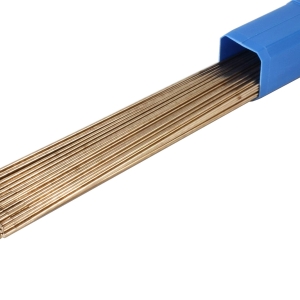

6010 Mild Steel Stick Welding Rods, commonly known as "6010 rods," are renowned for their ability to penetrate deeply into the base metal, making them ideal for welding in challenging conditions. These electrodes are widely used in industries such as construction, fabrication, and infrastructure development.

Understanding the Composition of 6010 Welding Rods

6010 welding rods are primarily composed of mild steel and a flux coating. The flux coating plays a vital role in shielding the weld pool from atmospheric contamination, ensuring clean and strong welds. Additionally, it facilitates the arc stability and provides easy slag removal after welding.

Advantages of Using 6010 Welding Rods

High Penetration

One of the key advantages of 6010 welding rods is their ability to penetrate deeply into the base metal, even when welding on dirty or rusty surfaces. This high penetration capability ensures strong and reliable welds, even in challenging conditions.

Versatility in Various Welding Positions

6010 welding rods are highly versatile and can be used in various welding positions, including flat, horizontal, vertical, and overhead. This versatility makes them suitable for a wide range of welding applications, providing flexibility to welders.

Suitable for Both AC and DC Welding

Another notable advantage of 6010 welding rods is their compatibility with both AC (Alternating Current) and DC (Direct Current) welding machines. This versatility allows welders to use these rods with different types of welding equipment, enhancing their usability in diverse settings.

Applications of 6010 Welding Rods

6010 welding rods find extensive applications across different industries due to their superior performance and reliability. Some common applications include:

- Pipeline Welding: 6010 rods are widely used in the construction and maintenance of pipelines, where strong and durable welds are essential for structural integrity and safety.

- Structural Welding: In construction projects, 6010 welding rods are employed for welding structural components such as beams, columns, and trusses, ensuring the structural stability of buildings and infrastructure.

- Shipbuilding: The marine industry relies on 6010 welding rods for fabricating and repairing ship structures, including hulls, decks, and bulkheads, due to their ability to produce high-quality welds in demanding environments.

Tips for Proper Storage and Handling of 6010 Welding Rods

To ensure optimal performance and longevity of 6010 welding rods, proper storage and handling are essential. Here are some tips to follow:

- Store the welding rods in a dry and moisture-free environment to prevent rust and degradation.

- Keep the rods in their original packaging or a dedicated rod oven to maintain their flux coating integrity.

- Handle the rods with care to avoid damage to the flux coating, which can affect weld quality.

Techniques for Using 6010 Welding Rods Effectively

Achieving excellent results with 6010 welding rods requires mastering the proper techniques. Here are some essential tips for using these rods effectively:

- Proper Amperage Settings: Adjust the welding machine to the recommended amperage range for the specific rod diameter to achieve optimal arc stability and penetration.

- Correct Electrode Angle: Maintain a slight drag angle (approximately 5-15 degrees) between the electrode and the workpiece to ensure proper arc control and penetration.

- Maintaining a Consistent Arc Length: Keep the arc length consistent throughout the welding process to prevent excessive spatter and ensure uniform penetration and fusion.

Safety Precautions When Using 6010 Welding Rods

While 6010 welding rods offer numerous benefits, it's essential to prioritize safety when using them. Here are some safety precautions to follow:

- Wear appropriate personal protective equipment (PPE), including welding helmets, gloves, and flame-resistant clothing, to protect against sparks, UV radiation, and heat.

- Ensure adequate ventilation in the welding area to minimize exposure to welding fumes and gases.

- Follow proper electrical safety practices, such as grounding the workpiece and maintaining the welding equipment in good condition, to prevent electrical hazards.

Comparing 6010 Welding Rods with Other Types of Electrodes

6010 welding rods are often compared with other types of electrodes, such as 6011 and 7018 rods. While each electrode has its unique characteristics and applications, 6010 rods stand out for their superior penetration and versatility in challenging welding conditions.

Troubleshooting Common Issues When Welding with 6010 Rods

Despite their excellent performance, welders may encounter some common issues when using 6010 welding rods. Here are some troubleshooting tips:

- Excessive Spatter: Adjust the amperage settings and arc length to reduce spatter and achieve a smoother weld bead.

- Incomplete Fusion: Increase the welding speed or adjust the electrode angle to ensure proper fusion between the base metal and the filler metal.

- Slag Inclusions: Clean the weld area thoroughly between passes to remove any slag buildup and ensure proper slag removal after welding.

Environmental Impact of 6010 Welding Rods

6010 welding rods, like other welding consumables, have environmental implications. While they produce minimal emissions during welding compared to other processes like oxy-fuel cutting, proper disposal of used electrodes and recycling of packaging materials can help minimize their environmental footprint.

Future Trends in Welding Technology and the Role of 6010 Rods

As welding technology continues to evolve, advancements in electrode design and manufacturing processes are expected. However, the fundamental qualities that make 6010 welding rods popular, such as their high penetration and versatility, are likely to remain relevant in the future.

Conclusion

In conclusion, 6010 Mild Steel Stick Welding Rods by MapleWeld offer unmatched performance and versatility, making them indispensable for various welding applications. With their high penetration, compatibility with different welding positions, and suitability for both AC and DC welding, these rods empower welders to achieve strong and reliable welds in challenging environments.

FAQs (Frequently Asked Questions)

- Are 6010 welding rods suitable for beginners?

- Yes, 6010 welding rods are suitable for beginners due to their forgiving arc characteristics and ease of use in various welding positions.

- Can 6010 welding rods be used for stainless steel welding?

- No, 6010 welding rods are specifically designed for mild steel welding and may not produce satisfactory results when used on stainless steel.

- How do I determine the correct amperage for welding with 6010 rods?

- Refer to the manufacturer's recommendations or conduct a test weld on scrap material to determine the optimal amperage settings for your specific welding setup.

- What is the shelf life of 6010 welding rods?

- When stored properly in a dry environment, 6010 welding rods can typically maintain their performance for up to one year.

- Can I weld overhead with 6010 welding rods?

- Yes, 6010 welding rods are suitable for overhead welding, but proper technique and control are essential to prevent weld defects.