Introduction:

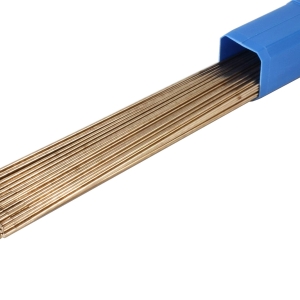

Welcome to the ultimate guide on welding with 5356 Aluminum TIG Welding Rods. In this comprehensive article, we'll delve into the intricacies of working with these rods, covering everything from their properties to welding techniques. Whether you're a seasoned welder or a novice looking to expand your skills, this guide has something for everyone.

Properties of 5356 Aluminum TIG Welding Rods:

5356 Aluminum TIG Welding Rods are renowned for their exceptional strength, corrosion resistance, and versatility. These rods contain 5% magnesium, offering excellent weldability and post-welding strength. Their 18" length provides ample material for various welding projects.

5356 Aluminum TIG Welding Rods exhibit:

- Superior corrosion resistance

- High tensile strength

- Excellent fluidity during welding

Selecting the Right Equipment:

Before diving into welding, it's crucial to ensure you have the right equipment. Here's what you'll need:

TIG Welding Machine:

Invest in a high-quality TIG welding machine capable of handling aluminum welding. Look for adjustable settings to control heat and current flow effectively.

Safety Gear:

Prioritize safety by wearing appropriate gear, including welding gloves, a welding helmet with a protective lens, and flame-resistant clothing.

Shielding Gas:

For welding aluminum, use pure argon or a mixture of argon and helium to shield the weld from atmospheric contamination.

Preparing Your Workspace:

Creating a conducive workspace is essential for successful welding. Follow these steps:

Ventilation:

Ensure adequate ventilation in your workspace to disperse fumes and prevent inhalation of harmful gases.

Cleanliness:

Thoroughly clean the welding surface to remove any dirt, grease, or debris that could affect weld quality.

Positioning:

Position the workpiece securely, ensuring it's stable and properly aligned for welding.

Welding Techniques with 5356 Aluminum TIG Welding Rods:

Mastering welding techniques is key to achieving precise and durable welds. Here are some essential techniques to hone:

Torch Angle and Travel Speed:

Maintain a consistent torch angle and travel speed to ensure uniform heat distribution and proper fusion.

Filler Metal Manipulation:

Practice proper filler metal manipulation techniques, such as dabbing and weaving, to control weld bead size and appearance.

Arc Length Control:

Maintain the optimal arc length, typically 1/8 inch, to prevent tungsten contamination and ensure a stable arc.

Post-Welding Treatment:

After welding, properly clean and inspect the weld for any defects. Consider post-weld treatments such as brushing or grinding to enhance weld aesthetics.

FAQs (Frequently Asked Questions):

What are the advantages of using 5356 Aluminum TIG Welding Rods?

5356 Aluminum TIG Welding Rods offer superior corrosion resistance, high tensile strength, and excellent weldability, making them ideal for various applications.

Can 5356 Aluminum TIG Welding Rods be used for outdoor projects?

Yes, thanks to their corrosion resistance, 5356 Aluminum TIG Welding Rods are suitable for outdoor projects exposed to harsh environmental conditions.

How do I store 5356 Aluminum TIG Welding Rods properly?

Store these rods in a dry environment away from moisture and humidity to prevent oxidation and maintain their quality.

What is the recommended welding technique for thin aluminum sheets?

When welding thin aluminum sheets, use a low heat input and employ techniques like tack welding to minimize distortion and warping.

Are 5356 Aluminum TIG Welding Rods compatible with other welding processes?

While primarily used for TIG welding, these rods can also be used for oxy-acetylene welding and MIG welding with appropriate adjustments.

How do I troubleshoot weld defects when using 5356 Aluminum TIG Welding Rods?

Inspect welds for common defects like porosity or lack of fusion. Adjust welding parameters and techniques accordingly, and ensure proper cleaning and preparation of the base metal.

Conclusion:

In conclusion, mastering the art of welding with 5356 Aluminum TIG Welding Rods opens up a world of possibilities for various projects. By understanding their properties, selecting the right equipment, and honing welding techniques, you can achieve impeccable welds with ease. Remember to prioritize safety and practice regularly to refine your skills.