Maximizing Productivity with 5-Axis CNC Machining in the Automotive Industry

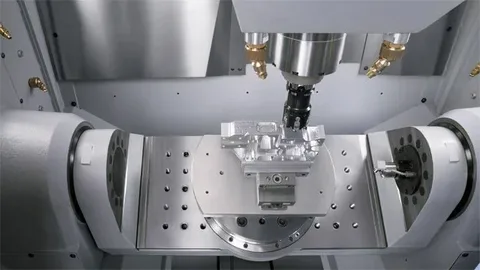

5-Axis CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape, particularly in the automotive industry, by enabling the production of complex, precise, and high-quality parts with remarkable speed. This advanced machining process involves five axes of movement that allow the tool to move along the X, Y, Z, and rotational axes, enabling unparalleled flexibility and efficiency. The ability to perform intricate cuts and shapes in a single setup reduces the time spent on retooling and aligning the workpiece, making it a highly advantageous technology for the fast-paced automotive industry.

In the automotive sector, precision, speed, and efficiency are critical factors in meeting stringent production deadlines and maintaining high-quality standards. 5-Axis CNC machining offers automotive manufacturers the ability to streamline their processes, improve accuracy, and enhance the overall productivity of their operations. From producing engine components and transmission parts to custom tooling, the integration of this technology has become an essential tool in automotive manufacturing. As the demand for complex, lightweight, and high-performance automotive parts continues to rise, 5-Axis CNC machining provides an essential advantage to automotive manufacturers aiming to stay competitive in the market.

Enhanced Precision and Accuracy in Automotive Part Production

One of the key advantages of 5-Axis CNC machining in the automotive industry is its ability to produce parts with superior precision and accuracy. The increased number of axes allows the machine to cut complex geometries with tight tolerances, which is critical in automotive part manufacturing. Whether it's producing engine blocks, suspension components, or intricate gears, the ability to make precise cuts in a single pass ensures the highest standards of quality. The elimination of multiple machine setups minimizes the risk of errors, providing automotive manufacturers with a more consistent and reliable production process.

Precision is particularly crucial when producing high-performance automotive parts that must meet specific weight, strength, and durability requirements. Traditional machining methods may require multiple setups and manual adjustments, which can introduce variances and lead to errors. 5-Axis CNC machining minimizes these risks by allowing for more comprehensive cutting options, such as undercuts and complex angles, which are often required in modern automotive designs. By ensuring that every part is manufactured to the exact specifications, 5-Axis CNC machining significantly enhances the quality and reliability of automotive components, ultimately boosting the performance and safety of vehicles on the road.

Increased Efficiency and Reduced Lead Times

The automotive industry is under constant pressure to reduce lead times and maximize efficiency in order to remain competitive. 5-Axis CNC machining offers a significant reduction in production time compared to traditional methods. The ability to work on multiple faces of a part simultaneously in a single setup eliminates the need for multiple machine operations and reduces the handling time for each workpiece. This streamlined process not only accelerates production but also reduces the risk of errors that can occur when parts are transferred between different machines.

Additionally, 5-Axis CNC machining allows manufacturers to produce more complex parts in a single pass. Components that would traditionally require multiple tools and setups can now be machined in one go, significantly improving throughput and reducing time spent on each part. This increased efficiency directly translates into shorter lead times, enabling automotive manufacturers to meet tight production schedules and deliver high-quality parts faster. With the growing demand for just-in-time manufacturing in the automotive industry, 5-Axis CNC machining offers a crucial advantage in terms of speed and efficiency, helping manufacturers keep up with the fast pace of the market.

Cost Reduction and Resource Optimization

Although the initial investment in 5-Axis CNC machines can be substantial, the long-term cost benefits outweigh the upfront costs. One of the most significant advantages of 5-Axis CNC machining in the automotive industry is its ability to reduce overall production costs. By consolidating multiple machine operations into a single process, manufacturers can reduce the number of machines, tools, and setups required for each part. This leads to savings in both equipment maintenance and energy consumption, as fewer machines are running simultaneously.

Moreover, 5-Axis CNC machining optimizes material usage. Traditional machining processes often involve excessive material waste, as parts are cut from larger blocks of material and may require additional trimming or adjustments. With 5-Axis CNC, manufacturers can more efficiently utilize material by creating parts with more intricate designs and fewer waste products. This reduces material costs and enhances sustainability by minimizing scrap. Overall, 5-Axis CNC machining contributes to resource optimization by reducing both direct and indirect costs, making it a cost-effective solution for automotive manufacturers seeking to improve their bottom line.

Versatility in Producing Complex Automotive Components

The automotive industry often requires highly specialized and complex components that demand advanced machining capabilities. 5-Axis CNC machining stands out in its ability to produce intricate and geometrically complex parts that would be difficult or impossible to create using traditional methods. For example, automotive manufacturers can produce components such as turbocharger housings, engine heads, or complex suspension systems with highly detailed features, all with high precision. The versatility of 5-Axis CNC machining allows for the creation of parts that require simultaneous multi-directional cutting, ensuring the production of complex shapes that are needed in modern vehicle designs.

This flexibility extends to the creation of custom tooling and prototypes for new automotive models. Manufacturers can quickly produce prototypes with high precision, allowing for faster iterations in the design and testing phase. The ability to create these parts efficiently and accurately also contributes to reduced development costs and faster time-to-market for new vehicle models. With the automotive industry’s increasing focus on lightweight, high-performance components, 5-Axis CNC machining provides the necessary capabilities to meet these evolving demands, supporting innovation and progress in the sector.

Conclusion

5-Axis CNC machining has proven to be a game-changer for the automotive industry by improving productivity, precision, and efficiency in manufacturing processes. As automotive manufacturers continue to push the boundaries of design and performance, the need for advanced manufacturing technologies like 5-Axis CNC machining becomes even more critical. The ability to create highly complex and precise components in a streamlined process is essential for maintaining competitiveness and meeting the ever-growing demands of the automotive market.

Looking ahead, 5-Axis CNC machining will likely continue to evolve with advancements in automation, artificial intelligence, and machine learning, further enhancing its capabilities and driving even greater productivity gains. As the automotive industry moves toward more sustainable and efficient manufacturing practices, 5-Axis CNC machining will play a key role in enabling the production of high-quality, complex automotive components in a cost-effective and resource-efficient manner. For automotive manufacturers, embracing this technology is not just a competitive advantage—it's an essential step toward success in a rapidly changing industry.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness