Failure Analysis Market Trends: Growth, Share, Value, Size, Industry Analsis and Forecast by 2028

"

Failure Analysis Market Size And Forecast by 2028

Despite its promising outlook, the Failure Analysis Market faces several challenges, including regulatory barriers, supply chain disruptions, and competitive pressures. However, the resilience of industry leaders and their focus on innovation and adaptability ensure the market’s sustained growth. By analyzing key growth drivers, opportunities, and future scope, this report serves as a critical resource for understanding the industry’s landscape and planning strategic initiatives.

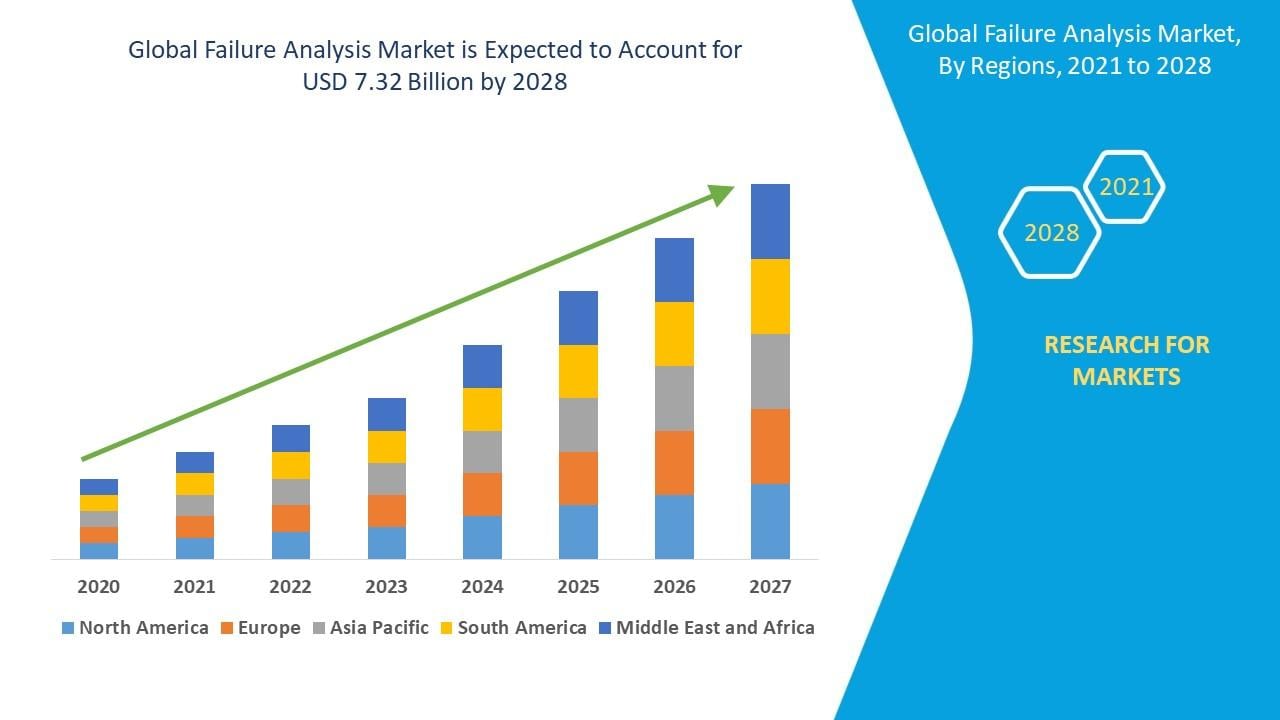

Failure analysis market is expected to reach USD 7.32 billion by 2028 witnessing market growth at a rate of 8.20% in the forecast period of 2021 to 2028.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-failure-analysis-market

Which are the top companies operating in the Failure Analysis Market?

The Top 10 Companies in Failure Analysis Market are leaders in their field, known for their strong market presence and innovative solutions. Their success is driven by their ability to adapt to market trends, invest in research and development, and meet customer needs effectively, making them key competitors in the Failure Analysis Market.

**Segments**

- **By Test**

- Non-Destructive Testing

- Destructive Testing

- **By Technique**

- Material Testing

- Surface Inspection

- Thermal Imaging

- Others

- **By End-User**

- Semiconductor Industry

- Automotive Industry

- Aerospace & Defense

- Electronics & Telecommunication

- Medical Devices

- Others

- **By Geography**

- North America

- Europe

- Asia-Pacific

- South America

- Middle East & Africa

The global failure analysis market is segmented based on test, technique, end-user, and geography. In terms of test, the market is categorized into non-destructive testing and destructive testing. Under techniques, the market includes material testing, surface inspection, thermal imaging, and others. The end-user segmentation comprises the semiconductor industry, automotive industry, aerospace & defense, electronics & telecommunication, medical devices, among others. Geographically, the market is analyzed across North America, Europe, Asia-Pacific, South America, and Middle East & Africa.

**Market Players**

- **Carl Zeiss AG**

- **Exova Group Limited**

- **Intertek Group plc**

- **Element Materials Technology**

- **SGS SA**

- **Bureau Veritas SA**

- **Evans Analytical Group LLC**

- **Amerapex Corporation**

- **Ametek Inc.**

- **Thermo Fisher Scientific Inc.**

The global failure analysis market is competitive with the presence of several key players leading the industry. Companies such as Carl Zeiss AG, Exova Group Limited, Intertek Group plc, Element Materials Technology, SGS SA, Bureau Veritas SA, Evans Analytical Group LLC, Amerapex Corporation, Ametek Inc., and Thermo Fisher Scientific Inc. are some of the prominent players in the market driving innovation and growth through strategic initiatives and technological advancements.

https://www.databridgemarketresearch.com/reports/global-failure-analysis-marketThe global failure analysis market is experiencing steady growth driven by various factors such as increasing demand for quality assurance in industries like semiconductor, automotive, aerospace, and electronics. The market segmentation based on test methods, including non-destructive testing (NDT) and destructive testing, caters to the diverse needs of industries seeking accurate and reliable analysis of materials and components. Non-destructive testing methods such as ultrasonic testing, radiographic testing, and visual inspection are crucial for identifying defects without altering the integrity of the tested material, ensuring product safety and reliability. On the other hand, destructive testing techniques involve examining the physical and chemical properties of materials through methods like tensile testing, charpy impact testing, and metallography, providing in-depth insights into material behavior under different conditions.

In terms of techniques, material testing plays a vital role in failure analysis, as it helps in determining the mechanical properties, chemical composition, and structural integrity of materials used in various industries. Surface inspection techniques, including visual inspection, dye penetrant testing, and magnetic particle testing, are instrumental in detecting surface cracks, corrosion, and other defects that could lead to component failure. Thermal imaging, another key technique in failure analysis, enables the monitoring of temperature distribution, heat flow, and thermal anomalies in components, helping identify potential failure points due to overheating or poor thermal management. Other techniques such as vibration analysis, acoustic emission testing, and infrared thermography further enhance the capabilities of failure analysis by offering multiple diagnostic tools to assess the health and performance of materials and components.

The segmentation based on end-users reflects the widespread adoption of failure analysis practices across industries to ensure product quality and safety. The semiconductor industry heavily relies on failure analysis to identify and rectify defects in microelectronic devices, ensuring high reliability and performance of electronic products. The automotive industry, facing stringent quality standards and safety regulations, utilizes failure analysis techniques to assess the structural integrity of vehicle components and ensure compliance with industry certifications. Aerospace and defense sectors leverage failure analysis to evaluate the performance of aircraft components, detect potential failures in critical systems, and enhance overall safety and operational efficiency. The electronics and telecommunication industry benefits from failure analysis in diagnosing faults in electronic circuits, devices, and communication systems, ensuring uninterrupted service delivery and customer satisfaction. Medical devices industry utilizes failure analysis to enhance the quality and reliability of medical equipment, ensuring optimal performance and patient safety.

In conclusion, the global failure analysis market is characterized by a diverse range of testing methods, techniques, end-users, and geographical presence, reflecting the importance of quality assurance and reliability in various industries. The market players mentioned are at the forefront of driving innovation and technological advancements, catering to the evolving needs of industries seeking robust failure analysis solutions to enhance product quality, safety, and performance. The market is poised for further growth as industries continue to prioritize failure analysis as a critical component of their quality management strategies, driving demand for advanced testing methods and techniques to mitigate risks and ensure operational excellence.The global failure analysis market is witnessing a substantial growth trajectory fueled by the increasing emphasis on quality assurance across a wide range of industries such as semiconductor, automotive, aerospace, and electronics. One of the key drivers behind this growth is the adoption of advanced testing methodologies, including non-destructive testing (NDT) and destructive testing, which are crucial for precisely analyzing the structural integrity and material properties of components and materials. Non-destructive testing methods like ultrasonic testing and radiographic testing play a pivotal role in identifying defects without compromising the integrity of the materials, thereby ensuring the safety and reliability of products. In contrast, destructive testing techniques such as tensile testing and metallography provide detailed insights into material behavior under varying conditions, offering a comprehensive understanding of failure mechanisms.

Material testing emerges as a critical technique within the failure analysis market, enabling industries to assess mechanical properties, chemical composition, and structural integrity of materials essential for product performance and durability. Surface inspection techniques, including visual inspection and dye penetrant testing, are instrumental in detecting surface defects and anomalies that could lead to potential failures in components. Thermal imaging techniques serve as a crucial tool for monitoring temperature differentials and identifying thermal irregularities within components, aiding in the prevention of overheating and thermal-related failures. Additional techniques such as vibration analysis and acoustic emission testing further enhance the diagnostic capabilities of failure analysis, allowing for comprehensive evaluations of material health and performance.

The segmentation by end-users underscores the widespread adoption of failure analysis practices across various industries to maintain product quality, compliance, and safety standards. Industries such as semiconductor and automotive heavily rely on failure analysis to ensure the reliability and performance of their products, especially in highly regulated environments where quality control is paramount. The aerospace and defense sectors leverage failure analysis to enhance aircraft component performance, improve system reliability, and uphold stringent safety standards. The electronics and telecommunication industry benefits from failure analysis by diagnosing faults in electronic systems, thereby ensuring seamless operational efficiency. The medical devices industry relies on failure analysis to enhance the quality and reliability of medical equipment, thus ensuring patient safety and regulatory compliance.

In conclusion, the global failure analysis market is poised for significant growth driven by the increasing demand for quality assurance and reliability across diverse industries. Key market players continue to drive innovation through strategic initiatives and technological advancements, catering to the evolving needs of industries seeking robust failure analysis solutions. As industries continue to prioritize quality management and operational excellence, the market is expected to witness sustained growth, with a focus on advanced testing methodologies to mitigate risks, enhance product quality, and ensure long-term reliability and safety.**Segments**

Global Failure Analysis Market, By Product:

- Transmission Electron Microscope

- Focused Ion Beam Systems

- Scanning Electron Microscopy

- Dual Beam Systems

- Others

Test:

- Contaminated Analysis

- Corrosion Investigation

- Fractography

- Metallography

- Mechanical Testing

- Chemical Analysis and Testing

- NDT

- Weld Testing

- Microstructure Evaluation

- Adhesive Identification

- Coating Contamination

- Thermal Mapping

- Electrical Overstress (EOS)/Electrostatic Discharge (EDS)

- Regulatory Compliance Testing

- Others

Technique:

- Destructive Physical Analysis

- Physics of Failure Analysis

- Fault Tree Analysis (FTA)

- Common-Mode Failure Analysis

- Failure Modes Effect Analysis (FMEA)

- Sneak Circuit Analysis

- Software Failure Analysis

- Others

Technology:

- Broad Ion Milling

- Focused Ion Milling

- Relative Ion Etching

- Secondary Ion Mass Spectroscopy

- Energy Dispersive X-Ray Spectroscopy

Application:

- Bio Science

- Electronics

- Renewable Energy

- Agriculture

- Oil and Gas

- Commercial Aerospace

- Defence

- Automotive

- Construction

- Chemical and Pharmaceutical

- Healthcare Equipment

- Food and Beverage

- Mining

- Polymer

- Paper and Fiber Material

- Ceramic and Glass

- Nanofabrication

- Others

Customers:

- Fab FA Labs Customers

- Fabless FA Labs Customers

- Specialty Labs Customers

- Other Customers

Country:

- U.S.

- Canada

- Mexico

- Brazil

- Argentina

- Rest of South America

- Germany

- Italy

- U.K.

- France

- Spain

- Netherlands

- Belgium

- Switzerland

- Turkey

- Russia

- Rest of Europe

- Japan

- China

- India

- South Korea

- Australia

- Singapore

- Malaysia

- Thailand

- Indonesia

- Philippines

- Rest of Asia-Pacific

- Saudi Arabia

- U.A.E

- South Africa

- Egypt

- Israel

- Rest of Middle East and Africa

**Market Players**

The major players covered in the failure analysis market report are:

- Hitachi High-Tech America, Inc.

- Thermo Fisher Scientific Inc.

- Carl Zeiss AG

- JEOL USA, Inc.

- TESCAN ORSAY HOLDING, a.s.

- Bruker

- HORIBA Europe GmbH

- Semilab Inc.

- A&D Company, Limited

- Motion X Corporation

- Eurofins Scientific

- Intertek Group plc

- Oxford Instruments

- RAITH GMBH

- Leica Microsystems

- Veeco Instruments Inc.

- ACCU TEST LABS

- Meiji Techno America

- Fibics Incorporated

- Applied Beams LLC

- Among other domestic and global players.

The global failure analysis market is driven by the expanding demand for accurate and reliable testing in various industries. The increasing emphasis on quality assurance in sectors like semiconductor, automotive, aerospace, and electronics has propelled the growth of the market. With a range of testing methods such as non-destructive and destructive testing, industries can ensure the integrity and safety of their products. Non-destructive techniques like ultrasonic and radiographic testing allow for defect identification without altering materials, ensuring product reliability. Destructive testing methods like tensile testing provide in-depth insights into material behavior, essential for comprehensive failure analysis.

Material testing is crucial in failure analysis, providing insights into mechanical properties and structural integrity. Surface inspection techniques play a key role in detecting surface defects that could lead to failures, ensuring quality and reliability. Thermal imaging helps monitor temperature distribution, identifying potential failure points due to overheating. Other techniques such as vibration analysis and acoustic emission testing offer further diagnostic capabilities, enhancing material health assessments.

The segmentation by end-users reflects the universal adoption of failure analysis practices across industries. From semiconductor and automotive to aerospace and defense, failure analysis is instrumental in ensuring product reliability and compliance with regulations. The electronics and telecommunication industry leverages failure analysis for fault diagnosis, ensuring operational efficiency. In healthcare, failure analysis enhances equipment quality and patient safety. As key players continue to drive innovation and technological advancements, the market is set for sustained growth, meeting the evolving needs of industries for robust failure analysis solutions.

Explore Further Details about This Research Failure Analysis Market Report https://www.databridgemarketresearch.com/reports/global-failure-analysis-market

Key Insights from the Global Failure Analysis Market :

- Comprehensive Market Overview: The Failure Analysis Market is experiencing significant growth, driven by technological advancements and increasing global demand.

- Industry Trends and Projections: Trends like automation and sustainability are shaping the market, with projections indicating continued growth over the next few years.

- Emerging Opportunities: There are emerging opportunities in green technologies, digital solutions, and under-served regional markets.

- Focus on R&D: Companies are investing heavily in R&D to innovate in areas such as AI, IoT, and sustainable product development.

- Leading Player Profiles: Key players like Company A and Company B lead the market through their strong product offerings and global presence.

- Market Composition: The market is fragmented, with a mix of established players and emerging startups targeting various niches.

- Revenue Growth: The Failure Analysis Market is seeing steady revenue growth, fueled by both consumer and commercial demand.

- Commercial Opportunities: Key commercial opportunities include expanding into emerging regions, digital transformation, and forming strategic partnerships.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/zh/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/ar/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/pt/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/de/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/fr/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/es/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/ko/reports/global-failure-analysis-market

https://www.databridgemarketresearch.com/ru/reports/global-failure-analysis-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness