How Molded Pulp Attributes Are Revolutionizing Product Protection and Sustainability

Molded pulp, a material that is gaining significant traction in various industries, is changing the way we think about product protection and sustainability. Made from recycled paper, cardboard, and other fibrous materials, molded pulp provides an eco-friendly alternative to traditional packaging options. With growing concerns about the environmental impact of plastic and Styrofoam, molded pulp attributes offer an innovative solution that not only protects products during transit but also contributes to a greener future. This article explores how the attributes of molded pulp are revolutionizing industries by enhancing product protection, reducing waste, and promoting sustainability.

The Rising Demand for Eco-Friendly Packaging Solutions

The shift towards eco-friendly packaging is one of the most significant trends in the modern business world. Consumers, regulators, and corporations alike are becoming more conscious of environmental impacts, leading to an increased demand for sustainable alternatives. Molded pulp, with its renewable and recyclable composition, is meeting this demand by offering a biodegradable and environmentally responsible solution. Its attributes make it an attractive option for companies looking to reduce their carbon footprint while maintaining product safety during shipping and handling.

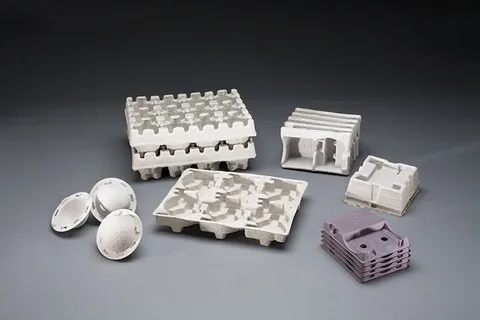

The versatility of molded pulp attributes also makes it suitable for a wide range of applications. From electronics and consumer goods to food and beverage packaging, molded pulp can be molded into complex shapes to fit various products securely. It serves as an effective replacement for plastic packaging, which has long been a significant contributor to environmental pollution. With growing pressure on businesses to adopt greener practices, the sustainability benefits of molded pulp are making it an essential component in the packaging industry.

Enhanced Product Protection Through Molded Pulp Attributes

One of the key reasons molded pulp has gained popularity in packaging is its ability to provide robust product protection. Molded pulp is designed to cushion and protect products during transportation, minimizing the risk of damage. Its shock-absorbing and vibration-damping properties are achieved through its porous and molded structure, which helps to distribute pressure evenly across the product. This makes molded pulp ideal for fragile or high-value items such as electronics, glassware, and even delicate food items like eggs.

The customizability of molded pulp attributes further enhances its effectiveness in product protection. Manufacturers can tailor the shape, thickness, and density of molded pulp inserts to fit the specific needs of a product. This ensures a snug and secure fit, preventing items from shifting or becoming damaged during transit. By offering superior protection while using sustainable materials, molded pulp packaging is rapidly becoming the go-to choice for businesses aiming to strike a balance between performance and environmental responsibility.

Reduced Environmental Impact with Molded Pulp

Molded pulp stands out for its minimal environmental footprint when compared to traditional packaging materials like plastic and Styrofoam. Made from post-consumer recycled paper, cardboard, and other biodegradable materials, molded pulp is a renewable resource that can be easily recycled after use. This means that its production and disposal result in less pollution and fewer greenhouse gas emissions than conventional packaging options. As a result, molded pulp plays a vital role in reducing waste and fostering a circular economy.

The recyclability and biodegradability of molded pulp are significant attributes in the ongoing fight against plastic pollution. Unlike plastic, which can take hundreds of years to decompose and is often harmful to wildlife, molded pulp breaks down quickly in natural environments, leaving no toxic residues. This natural decomposition ensures that molded pulp does not contribute to landfills or oceans, making it a superior choice for environmentally-conscious businesses looking to reduce their impact on the planet.

Cost-Effective Benefits of Molded Pulp Packaging

While molded pulp is renowned for its sustainability, it also offers significant cost-effective advantages for businesses. In comparison to plastic packaging, molded pulp is often more affordable due to its use of recycled materials and the relatively low cost of production. Manufacturers can take advantage of economies of scale by producing large quantities of molded pulp packaging at a fraction of the cost of plastic alternatives. Furthermore, the lightweight nature of molded pulp reduces shipping costs, as it adds less weight to shipments and decreases transportation expenses.

The cost-effectiveness of molded pulp also extends to its ability to enhance the overall product packaging process. Its customization options allow businesses to create efficient and protective packaging solutions that minimize material waste. As molded pulp is designed to fit products securely, companies can optimize packaging space, ensuring that they use the smallest amount of material possible while still providing robust protection. This minimizes unnecessary waste and lowers the overall cost of packaging, making it a win-win solution for both businesses and the environment.

Molded Pulp’s Future in Sustainable Packaging

The future of molded pulp in packaging looks promising, with new innovations continuously enhancing its attributes and broadening its applications. As businesses strive to meet consumer demand for more sustainable solutions, molded pulp is positioned to become a central player in the global packaging landscape. In addition to the traditional use of molded pulp for protecting fragile items, research and development efforts are exploring new ways to improve its functionality and versatility. These innovations include integrating molded pulp with other sustainable materials to create hybrid packaging solutions that offer even greater durability and performance.

With the global push for sustainability growing stronger, molded pulp's potential to revolutionize the packaging industry is becoming more apparent. As technology advances and molded pulp attributes evolve, it is likely that this material will be used in even more creative and efficient ways. By embracing molded pulp, companies can not only improve product protection but also play an active role in reducing their environmental footprint and contributing to a more sustainable future.

Conclusion

Molded pulp attributes are transforming the packaging industry by offering sustainable, cost-effective, and high-performing solutions for product protection. Its ability to protect delicate items, reduce environmental impact, and replace plastic packaging is helping businesses meet the growing demand for eco-friendly alternatives. As molded pulp continues to evolve and expand its applications, it is clear that this material is poised to revolutionize product packaging in ways that benefit both businesses and the planet. By leveraging the attributes of molded pulp, companies can reduce waste, lower costs, and contribute to a more sustainable future while still ensuring the safety of their products.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness