Bellow Sealed Globe Valve: Enhancing Efficiency and Reliability in Industrial Applications

Industrial processes rely heavily on high-performance valves to ensure safe, efficient, and reliable operations. Among the various valve types available, Bellow Sealed Globe Valves have emerged as an essential component for industries that demand zero leakage, high durability, and superior sealing performance. Their unique construction and advanced features make them ideal for critical applications across chemical, pharmaceutical, petrochemical, and power generation industries.

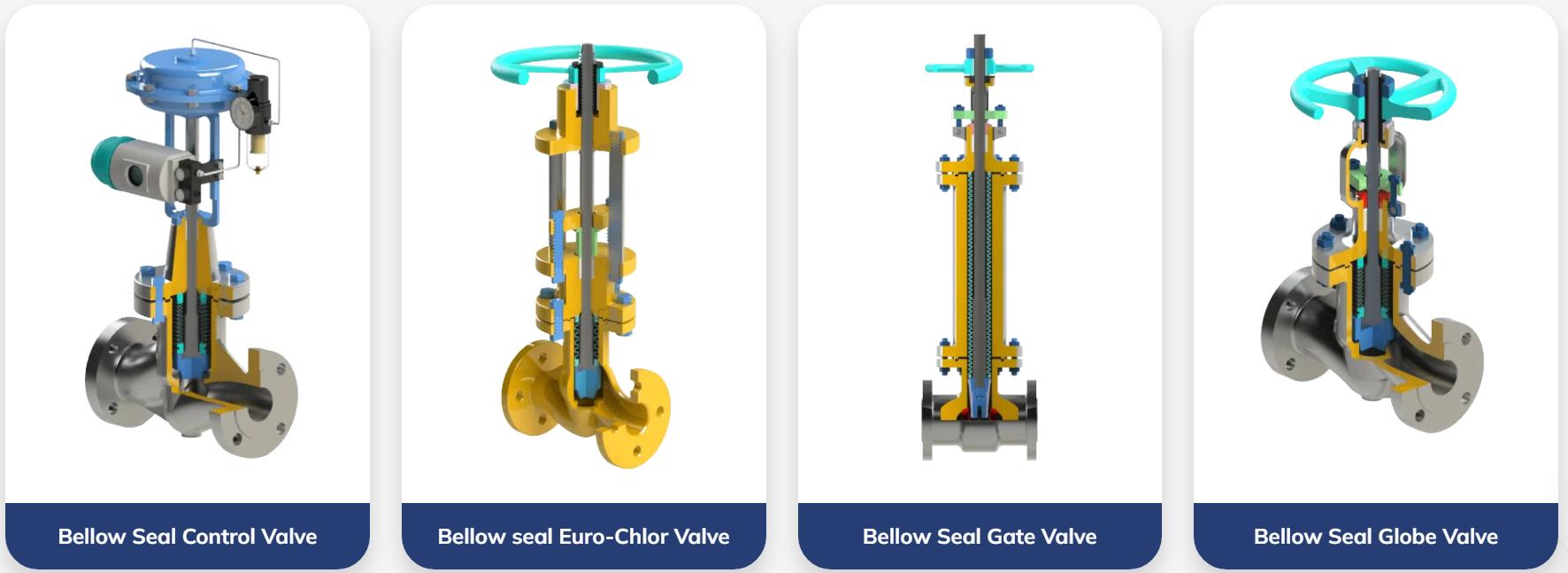

What is a Bellow Sealed Globe Valve?

A Bellow Sealed Globe Valve is a type of globe valve specifically designed to provide a leak-proof seal. Unlike traditional globe valves, which rely on packing materials to seal the stem, bellow sealed globe valves use a flexible metal bellows to create an airtight barrier. This eliminates the risk of fugitive emissions, ensuring that no fluids or gases escape into the environment.

The valve operates with a linear motion, making it ideal for regulating or throttling flow. Its robust design and advanced sealing mechanism provide exceptional reliability, even in high-pressure and high-temperature applications.

Key Features of Bellow Sealed Globe Valves

-

Flexible Metal Bellows

The bellows act as a dynamic seal, isolating the valve stem from the process fluid. This design ensures that even under extreme operating conditions, there is no leakage or contamination. -

Zero Leakage Design

The valve’s construction eliminates external leakage, making it compliant with stringent environmental and safety standards. It is especially beneficial for handling toxic, hazardous, or corrosive media. -

Durable Materials

These valves are typically made from high-grade materials such as stainless steel, carbon steel, and alloy steel, ensuring excellent resistance to corrosion and wear. -

High Cycle Life

The bellow seal is engineered to withstand thousands of cycles without failure, reducing maintenance needs and operational downtime. -

Enhanced Safety

By preventing fugitive emissions, bellow sealed globe valves enhance workplace safety and minimize environmental impact.

Applications of Bellow Sealed Globe Valves

The unique advantages of bellow sealed globe valves make them suitable for various critical applications, including:

-

Chemical Processing

These valves are ideal for handling aggressive chemicals, acids, and hazardous fluids, ensuring no leakage during operations. -

Pharmaceutical Industry

In processes requiring high levels of purity, such as the production of active pharmaceutical ingredients (APIs), bellow sealed valves prevent cross-contamination and maintain product quality. -

Power Generation

These valves are often used in steam systems and other high-temperature applications where leakage can be detrimental to efficiency and safety. -

Oil and Gas Industry

Bellow sealed globe valves are used in refineries and petrochemical plants to handle volatile hydrocarbons, ensuring safe and reliable performance. -

Cryogenic Applications

Their ability to operate efficiently at extremely low temperatures makes them suitable for handling liquefied gases like LNG and nitrogen.

Advantages of Bellow Sealed Globe Valves

-

Environmentally Friendly

The zero-leakage design significantly reduces fugitive emissions, contributing to environmental sustainability. -

Cost-Effective Operation

The long service life and low maintenance requirements of these valves translate to reduced operational costs over time. -

Compliance with Standards

These valves are designed to meet international standards such as ISO 15848 and TA-Luft, ensuring high-quality performance and reliability. -

Versatility

Available in various sizes, pressure ratings, and materials, these valves can be customized to meet specific application requirements.

Choosing the Right Bellow Sealed Globe Valve

Selecting the appropriate bellow sealed globe valve for your application requires careful consideration of factors such as:

- Process Media: The chemical compatibility of the valve material with the fluid being handled is crucial.

- Operating Conditions: Evaluate temperature, pressure, and flow requirements to ensure optimal performance.

- Size and Configuration: Choose the right size and connection type to suit your system design.

- Compliance: Ensure the valve meets relevant safety and environmental standards.

Working with a trusted valve manufacturer can simplify the selection process, providing you with expert guidance and high-quality products tailored to your needs.

Conclusion

Bellow Valves are an indispensable solution for industries requiring robust, leak-proof, and reliable performance. Their ability to enhance safety, minimize environmental impact, and improve operational efficiency makes them a preferred choice for critical applications.

When it comes to sourcing premium-quality bellow sealed globe valves, Freture Techno Pvt. Ltd. stands out as a trusted manufacturer. With a commitment to innovation and quality, Freture Techno Pvt. Ltd. delivers reliable valve solutions that meet the diverse needs of industries worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness