3D Printing Elastomers Market Opportunities, Statistics, COVID-19 Impact, and Forecast by 2032

3D printing elastomers represents an exciting frontier in additive manufacturing, enabling the production of flexible, rubber-like materials with precision and customization. Elastomers, known for their elasticity, durability, and resilience, are traditionally used in industries such as automotive, medical, and consumer goods. By incorporating 3D printing technologies, manufacturers can now design and produce elastomeric components that meet specific performance requirements, including varying levels of flexibility, hardness, and durability. This innovation allows for rapid prototyping, small-batch production, and the ability to create complex geometries that would be challenging or impossible using conventional manufacturing techniques. The ability to print elastomers with high precision is also transforming industries by providing more efficient, cost-effective solutions for producing custom products.

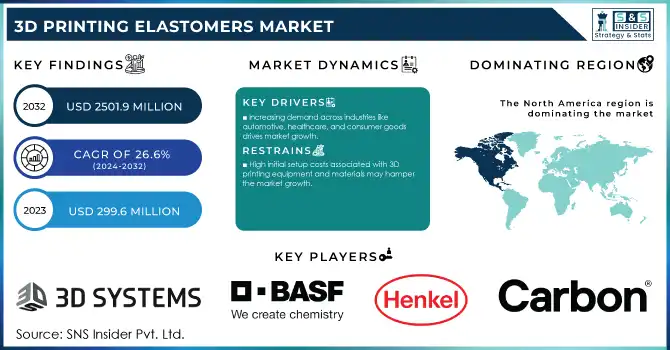

The 3D Printing Elastomers Market size was USD 299.6 million in 2023 and is expected to reach USD 2501.9 million by 2032 and grow at a CAGR of 26.6% over the forecast period of 2024-2032.

Future Scope

The future of 3D printing elastomers is poised for significant growth, driven by advancements in materials science and additive manufacturing technologies. As the demand for customized, high-performance components continues to increase, 3D printed elastomers are expected to see broader adoption across various sectors, including automotive, healthcare, consumer products, and industrial applications. Innovations in material formulations, such as improved thermal, chemical, and mechanical properties, will enable the production of more specialized elastomeric parts. The integration of 3D printing with the Internet of Things (IoT) and digital twin technology is also expected to improve the precision and performance of 3D printed elastomers in complex systems. With the rise of on-demand manufacturing, 3D printed elastomers could become increasingly important for creating personalized products and solutions in industries ranging from prosthetics to automotive sealing systems.

Emerging Trends

Several emerging trends are shaping the 3D printing elastomers market. The integration of multi-material 3D printing systems, which can combine elastomers with other materials like metals or plastics, is allowing for more sophisticated parts with enhanced mechanical properties. Additionally, advancements in printable elastomeric inks and resins are expanding the range of 3D printable elastomer types, such as thermoplastic elastomers (TPEs) and liquid silicone rubber (LSR). Another key trend is the adoption of 3D printing in industries that require high customization and low-volume production, such as the medical field, where custom prosthetics, orthotics, and implants are being created using elastomers. Furthermore, as sustainability becomes more important in manufacturing, the development of biodegradable and recyclable elastomeric materials for 3D printing is gaining attention.

Drivers

The key drivers of the 3D printing elastomers market include the growing demand for customized, high-performance parts and the increasing need for rapid prototyping in various industries. The ability to create complex, flexible parts with high precision is driving innovation in sectors like automotive, where lightweight, durable, and flexible components are required. In healthcare, the ability to produce custom prosthetics and orthotics tailored to individual patients is another major driver. The shift toward on-demand manufacturing and the reduction of material waste compared to traditional manufacturing methods are also contributing to the growth of 3D printing elastomers. Furthermore, as the availability of high-performance elastomeric materials for 3D printing increases, more industries are adopting this technology for small-batch and mass-customized production.

Restraints

While the potential for 3D printing elastomers is vast, the technology faces several challenges. One major constraint is the limited availability of elastomeric materials that are compatible with 3D printing processes. Although advances are being made, many elastomers still lack the required material properties for certain industrial applications, such as high-temperature resistance or long-term durability. Additionally, the speed of 3D printing elastomers remains slower compared to traditional manufacturing methods, which can hinder its adoption for large-scale production. The cost of 3D printing equipment and materials can also be a barrier, particularly for smaller companies. Moreover, the need for specialized expertise to operate 3D printers and optimize designs for elastomeric materials is another factor limiting widespread adoption.

Key Points

· 3D printing elastomers enables the creation of flexible, durable, and custom components with high precision.

· The technology is used across industries like automotive, healthcare, and consumer goods, offering rapid prototyping and low-volume production.

· Emerging trends include multi-material printing, advances in printable elastomeric inks, and the use of 3D printing for customized medical products.

· Drivers include the demand for high-performance, personalized components, as well as the need for rapid prototyping and on-demand manufacturing.

· Challenges include material limitations, slower production speeds, and the cost of 3D printing equipment and materials.

Conclusion

3D printing elastomers is revolutionizing the manufacturing of flexible and durable parts across a wide range of industries. The ability to produce custom, high-performance components with complex geometries offers significant advantages over traditional manufacturing techniques, particularly in sectors that require rapid prototyping and low-volume production. As advancements continue in material science and 3D printing technologies, the adoption of 3D printed elastomers is expected to grow, offering more sustainable and cost-effective solutions for industries such as automotive, healthcare, and consumer goods. However, challenges such as material availability, production speed, and costs must be addressed for 3D printing elastomers to reach its full potential in mainstream manufacturing. The continued development of high-performance materials and improved printing systems will be essential for expanding the possibilities and applications of 3D printing elastomers in the future.

Read Full Report @ https://www.snsinsider.com/reports/3d-printing-elastomers-market-1450

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness