Coating Equipment Market Trends, Growth, Top Companies, Revenue, and Forecast to 2032

Coating equipment plays a pivotal role in applying protective and functional coatings to a wide range of substrates, enhancing surface performance, durability, and aesthetic appeal. Used in various industries such as automotive, aerospace, electronics, construction, and packaging, coating equipment ensures that materials are protected against corrosion, wear, and environmental factors. These systems apply coatings such as paints, powders, films, and lubricants to surfaces, improving their resistance to scratches, chemicals, UV radiation, and other elements. With increasing demand for precision, efficiency, and customization in industrial processes, coating equipment is evolving with advanced technologies, including automated systems, robotic arms, and digital control mechanisms, ensuring consistent quality and faster production cycles.

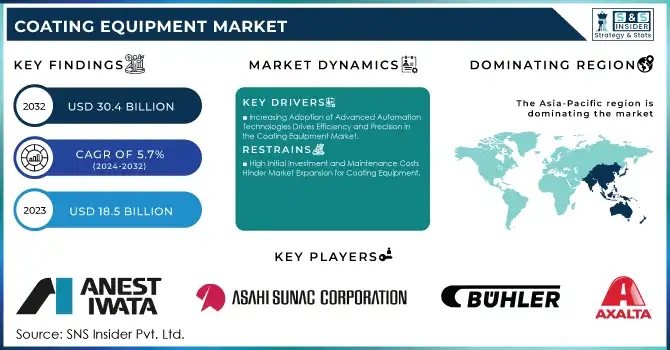

The Coating Equipment Market Size was valued at USD 18.5 billion in 2023 and is expected to reach USD 30.4 billion by 2032 and grow at a CAGR of 5.7% over the forecast period 2024-2032.

Future Scope

The future of coating equipment looks promising, driven by innovations in material science, automation, and sustainability. The trend toward eco-friendly coatings, such as water-based and low-VOC (volatile organic compound) alternatives, is encouraging manufacturers to develop more advanced and environmentally responsible coating equipment. Smart coating systems that integrate sensors, AI, and machine learning for real-time monitoring and quality control are expected to revolutionize the industry by increasing efficiency and reducing waste. Additionally, as industries continue to emphasize the need for durable and functional surfaces, coating equipment that supports multi-functional coatings, including corrosion protection, heat resistance, and aesthetic enhancement, is anticipated to witness significant growth.

Emerging Trends

A key emerging trend in the coating equipment market is the adoption of automation and robotics, which enables faster, more precise, and consistent application of coatings. Robotic arms are becoming integral to coating processes, particularly in industries like automotive and aerospace, where high precision is required. Additionally, digitalization is taking center stage, with systems now featuring advanced control units that optimize the coating process and reduce human error. The growing focus on sustainability has also led to a surge in demand for coating equipment that applies eco-friendly, low-emission coatings, including powder coatings and water-based paints. Furthermore, there is an increasing trend toward coating equipment that can apply multi-layer coatings in a single pass, enhancing the protection and functionality of the coated surface.

Drivers

The coating equipment market is driven by a range of factors, including technological advancements, increased demand for high-performance coatings, and the growing need for environmental sustainability. Automation in coating systems allows for faster production cycles, greater precision, and the ability to handle complex geometries. The automotive and aerospace industries are particularly influential, requiring coatings that offer exceptional durability, corrosion resistance, and heat protection. Additionally, the push for greener products and manufacturing processes has led to innovations in environmentally friendly coating technologies, further fueling the demand for advanced coating equipment. The rise in consumer demand for aesthetically appealing products, along with increased awareness of the importance of surface protection, also contributes to the market's growth.

Restraints

Despite their advantages, coating equipment faces several challenges. High initial investment costs for advanced coating systems can be a barrier for small and medium-sized enterprises (SMEs), particularly in industries that require highly specialized coating processes. The complexity of integrating new coating technologies with existing manufacturing infrastructure also presents difficulties for some companies. Furthermore, the need for continuous maintenance and the potential for coating defects during the application process can impact overall operational efficiency. The market also faces regulatory challenges related to the use of certain chemicals in coatings, especially those that contain high levels of VOCs or other harmful substances.

Key Points

· Coating equipment is essential for applying protective and functional coatings to a variety of surfaces, improving durability and performance.

· The future of coating equipment includes automation, smart technologies, and eco-friendly coating solutions.

· Emerging trends include robotic automation, multi-layer coatings, and increased use of low-emission, sustainable coatings.

· Key drivers include the demand for high-performance coatings, automation in manufacturing, and the push for environmental sustainability.

· Restraints include high initial costs, integration challenges, and regulatory constraints on harmful substances.

Conclusion

Coating equipment is a vital component in the manufacturing of products that require enhanced surface properties, including durability, resistance to corrosion, and aesthetic appeal. As industries demand higher performance and sustainability, coating equipment is evolving to meet these needs with advanced technologies such as automation, robotics, and eco-friendly coatings. While challenges such as initial investment costs and regulatory hurdles persist, the future of coating equipment remains bright, driven by continuous innovations and growing industry requirements. With the increasing focus on environmental impact, coating equipment that supports sustainable practices and efficient production will play an increasingly important role in the global manufacturing landscape.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/2262

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness