Green and Bio Polyols Market with Dynamics, Segments, and Forecast by 2032

Green and bio polyols are an emerging class of polyols derived from renewable, bio-based feedstocks, which are used as essential components in the production of polyurethane (PU) products. Polyurethane is a versatile material found in various applications, ranging from flexible foams used in furniture and automotive seating to rigid foams for insulation and coatings. Traditional polyols used in polyurethane production are primarily petroleum-based, contributing to environmental concerns related to resource depletion and carbon emissions. Green and bio polyols, in contrast, are sourced from renewable agricultural products such as soybeans, castor oil, and corn, as well as waste by-products. By replacing conventional petrochemical-based polyols with bio-based alternatives, manufacturers can reduce their reliance on fossil fuels, lower their carbon footprint, and create more sustainable PU products. As the global focus shifts toward environmental responsibility, the demand for green and bio polyols has gained significant momentum across industries looking to align with sustainability goals.

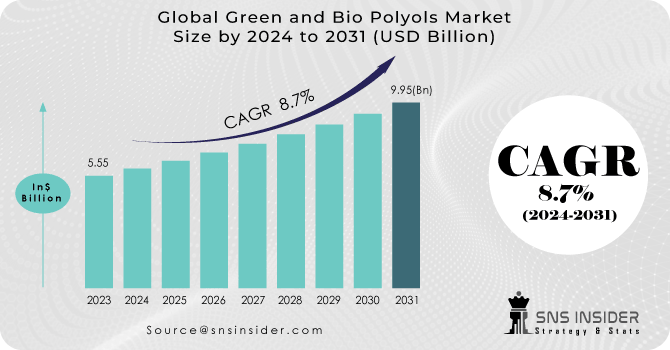

The Green and Bio Polyols Market size was valued at USD 5.02 billion in 2023. It is expected to grow to USD 10.20 billion by 2031 and grow at a CAGR of 9.3% over the forecast period of 2024-2031.

Future Scope

The future of green and bio polyols is promising, with increasing environmental concerns and regulatory pressures pushing industries to seek out sustainable alternatives. The demand for bio-based polyols is expected to rise in parallel with the growing need for eco-friendly materials in various industries such as automotive, construction, furniture, and packaging. As polyurethane products continue to be indispensable in a wide range of applications, the use of green and bio polyols will become a cornerstone of sustainable production processes. Innovations in biopolymer research are anticipated to lead to the development of even more efficient, cost-effective, and high-performance bio-based polyols, enhancing the competitiveness of green polyols in comparison to their petroleum-based counterparts. Additionally, as governments worldwide set stricter sustainability and carbon reduction goals, there will be a substantial push for industries to adopt more environmentally friendly practices. This trend will continue to accelerate the adoption of green and bio polyols, particularly in highly regulated markets such as Europe and North America.

Emerging Trends

A key trend in the green and bio polyols market is the increasing shift toward the adoption of bio-based raw materials to reduce dependency on fossil fuels. This trend is driven by growing consumer demand for sustainable products, as well as stricter regulations governing environmental impact. Bio-based polyols derived from renewable resources such as plant oils, sugars, and agricultural waste are gaining traction due to their potential to lower greenhouse gas emissions and reduce the carbon footprint of polyurethane products. Additionally, advancements in the development of more efficient production methods for bio polyols, such as enzymatic or microbial processes, are improving the cost-effectiveness and scalability of bio-based polyol production. Furthermore, the increasing use of green and bio polyols in non-foam applications, such as coatings, adhesives, sealants, and elastomers, is expanding the scope of their potential use. Another emerging trend is the growing adoption of circular economy principles, where bio polyols are being integrated into closed-loop systems, reducing waste and supporting recyclability.

Drivers

Several factors are driving the growth of green and bio polyols in the marketplace. Increasing consumer demand for sustainable and environmentally responsible products is one of the primary drivers, with end-users across industries seeking out alternatives to traditional petroleum-based polyurethanes. As environmental awareness rises, many companies are prioritizing sustainability in their supply chains and manufacturing processes, prompting the switch to bio-based materials. The adoption of stricter environmental regulations, particularly in markets like Europe and North America, is another key factor pushing the use of green polyols. Regulatory bodies are instituting more stringent requirements for carbon emissions, material sourcing, and waste management, encouraging manufacturers to look for renewable, non-toxic alternatives to traditional polyols. Additionally, innovations in the agricultural sector and biopolymer research are leading to more efficient and cost-competitive bio-based polyols, making them more accessible to a broader range of industries. As sustainability continues to be a central focus in global manufacturing, the demand for green and bio polyols will continue to rise, aligning with global efforts to reduce the environmental impact of synthetic materials.

Restraints

Despite the clear advantages of green and bio polyols, there are some challenges that could impede their broader adoption. One of the main obstacles is the higher cost associated with bio-based polyols compared to traditional petrochemical-based alternatives. Although prices are expected to decrease as production methods improve and economies of scale are realized, bio polyols are still considered more expensive for some manufacturers. This price differential can be a barrier, especially in price-sensitive industries such as packaging and consumer goods. Additionally, there may be concerns related to the performance characteristics of bio-based polyols, particularly in applications where durability and strength are critical. While advancements in material science are improving the properties of green polyols, some industries may still prefer the predictable and proven performance of conventional polyols. Furthermore, the availability of raw materials for bio polyol production, such as specific agricultural crops, may face supply chain disruptions, impacting the consistency and reliability of bio-based polyol production. Lastly, there is ongoing research to ensure that bio polyols are not only sustainable but also capable of meeting the technical performance requirements of various polyurethane products.

Key Points

· Green and bio polyols are bio-based alternatives to petroleum-derived polyols used in the production of polyurethane (PU) materials.

· The market for green and bio polyols is driven by growing consumer demand for sustainable, eco-friendly products and increasing environmental regulations.

· Emerging trends include the use of renewable feedstocks such as plant oils and agricultural waste, as well as innovations in biopolymer research and efficient production processes.

· Drivers of market growth include stricter sustainability regulations, increasing environmental awareness, and advancements in bio-based material technologies.

· Restraints include the higher cost of bio polyols compared to conventional polyols, performance challenges in certain applications, and potential supply chain issues for raw materials.

· The future of green and bio polyols looks promising, with continued advancements in bio-based technologies and a growing focus on sustainability in manufacturing.

In conclusion, green and bio polyols represent a significant advancement in the move toward more sustainable and environmentally responsible materials. As industries and consumers demand more eco-friendly products, the use of bio-based polyols will continue to grow, offering a cleaner alternative to traditional polyurethanes. With ongoing research, improvements in production techniques, and supportive regulatory frameworks, green and bio polyols are set to play an essential role in shaping the future of polyurethane production and contributing to a more sustainable global economy.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/1704

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness