Fiberglass Platforms Explained: Lightweight, Sturdy, and Dependable

When considering materials for industrial or commercial use, many people weigh durability, weight, and cost as critical factors. Fiberglass platforms strike a balance between all three, offering a versatile solution that’s hard to ignore. These platforms are not just about being lightweight; they boast impressive strength and durability, making them a favorite in environments where metal and wood might fall short. But what makes them so dependable? Let’s break it down.

What are Fiberglass Platforms?

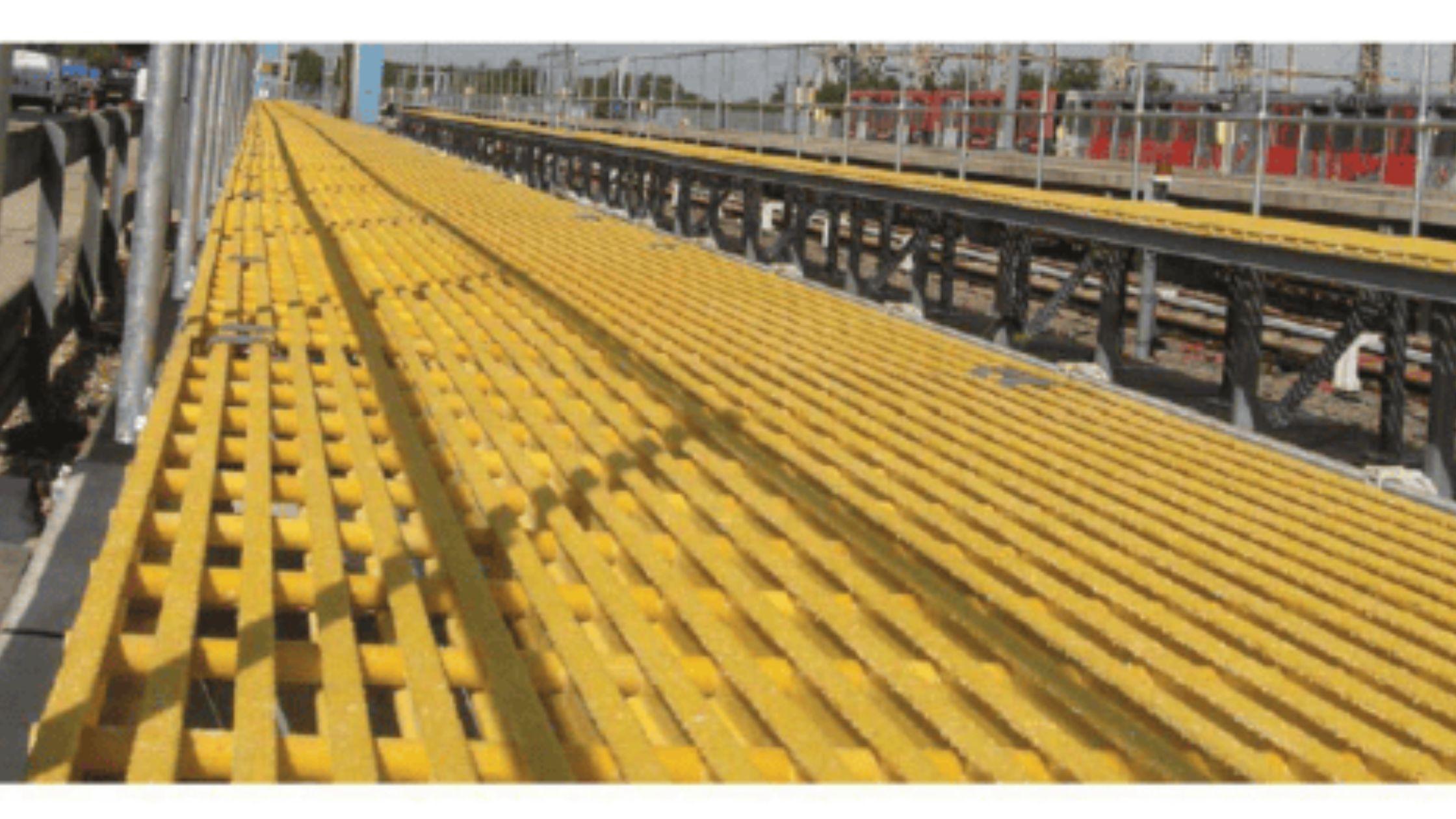

Fiberglass platforms are structures crafted from fiberglass-reinforced plastic (FRP), a material that combines glass fibers and resin to create a robust composite. The result? A material resistant to corrosion, lightweight to handle, and incredibly sturdy under pressure. These platforms are commonly used in industrial plants, marine environments, and construction sites where other materials might degrade over time.

Unlike traditional materials, fiberglass doesn't rust, warp, or absorb moisture. This unique quality makes it ideal for environments that face constant exposure to harsh weather or chemicals. It's easy to see why industries are turning to fiberglass platforms as a long-term solution.

How Do Fiberglass Platforms Compare to Metal or Wood?

Fiberglass platforms often outperform metal and wood alternatives in critical areas like longevity, maintenance, and versatility. Metal structures, while strong, are prone to rust and corrosion, especially in humid or salty environments. Wood, on the other hand, may rot, crack, or become a playground for termites over time.

Fiberglass provides a middle ground—lightweight enough to transport easily yet durable enough to handle heavy loads. It’s non-conductive as well, offering an added layer of safety in electrical environments. Have you ever tried lugging around a steel platform? With fiberglass, your back—and your team—will thank you.

Why Choose Fiberglass Plates for Added Strength?

Sometimes, the core structure of a platform needs reinforcement. Enter fiberglass plates. These plates can be used as an additional layer of protection or support, depending on the application. They are especially useful in high-traffic areas where wear and tear are inevitable.

Fiberglass plates can also be customized to fit specific dimensions, making them a flexible choice for businesses with unique needs. Their non-slip surface ensures safety, even in environments prone to spills or moisture. If you're looking to add extra durability to your fiberglass platforms, these plates are the perfect pairing.

The Role of Kentec Composites in the Fiberglass Industry

Kentec Composites isn’t your average manufacturer. While many companies stick to meeting the bare minimum standards, Kentec goes further, ensuring every product exceeds industry expectations. By using only the highest quality raw materials, Kentec creates fiberglass platforms that outlast and outperform competitors.

But it’s not just about durability. Kentec’s focus on reliability means you get materials that won't let you down in critical moments. Whether you're working in a high-stress industrial environment or managing a small workshop, Kentec’s commitment to quality provides peace of mind.

Key Advantages of Fiberglass Platforms

There’s a laundry list of reasons to choose fiberglass platforms, but here are a few highlights that stand out:

-

Corrosion Resistance: Perfect for marine, chemical, or humid environments.

-

Lightweight Design: Easier to transport and install than traditional materials.

-

Strength-to-Weight Ratio: Strong enough to handle heavy loads without being bulky.

-

Safety Features: Non-conductive and slip-resistant surfaces make them ideal for hazardous areas.

-

Low Maintenance: Forget the constant upkeep; fiberglass requires minimal care.

No one enjoys dealing with materials that need frequent replacement or repairs. Fiberglass platforms offer a long-term solution that saves both time and money.

Applications That Demand Fiberglass

From wastewater treatment plants to offshore oil rigs, fiberglass platforms find their way into numerous industries. Why? Because they can handle environments that would typically wear down other materials.

For instance, in the marine sector, saltwater exposure is a constant threat to metal structures. Fiberglass thrives here, resisting the corrosion that can weaken metal over time. In the industrial world, chemical exposure often rules out wood or metal—fiberglass takes the hit and keeps going. Wherever durability meets extreme conditions, fiberglass is likely to be the hero.

How to Maintain Fiberglass Platforms?

One of the standout benefits of fiberglass is its low-maintenance nature. That doesn’t mean you can set it and forget it entirely, though. Routine inspections are essential to ensure the structure remains in peak condition.

Cleaning fiberglass platforms is straightforward: a little soap, water, and a soft brush can keep them looking new. For tougher stains, a mild cleaning solution works wonders. Avoid harsh chemicals, as these can degrade the resin over time. The goal? Keep your platforms strong without overcomplicating their care.

The Role of Fiberglass Plates in Extreme Conditions

In situations where platforms are exposed to extreme temperatures or heavy impacts, fiberglass plates add an extra layer of security. These plates distribute weight evenly and protect the underlying structure from damage.

Imagine a warehouse with forklifts constantly moving heavy loads. The wear and tear on a regular platform would be significant. Fiberglass plates prevent premature damage, ensuring the platform lasts for years without needing major repairs. It’s the perfect example of how a small addition can make a big difference.

Making the Switch to Fiberglass: Is It Worth It?

If you’re still on the fence about transitioning to fiberglass platforms, consider this: the initial investment pays off in longevity and reduced maintenance costs. While the upfront cost might be slightly higher than wood or lower-grade metals, the long-term savings are undeniable.

Fiberglass platforms and plates provide a durable, reliable, and cost-effective solution for industries that demand the highest performance standards. And with Kentec Composites, you’re not just buying a product—you’re investing in peace of mind, knowing your materials are built to last.

Wrapping It Up

Fiberglass platforms and plates offer a unique combination of lightweight construction, impressive durability, and resistance to environmental damage. From their ability to outperform traditional materials to their adaptability in extreme conditions, it’s clear why so many industries are making the switch.

Choosing Kentec Composites ensures you’re working with materials crafted to exceed expectations. Whether it’s a high-traffic industrial site or a marine environment, fiberglass provides a dependable solution that stands the test of time. So, the next time you’re looking for a material that can handle whatever life throws at it, consider fiberglass—a lightweight, sturdy, and dependable choice.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness