Basalt Fiber Market Boosting the Growth Worldwide by 2032

Basalt fiber is an advanced composite material derived from volcanic rock, specifically basalt, which is naturally abundant and offers exceptional properties that make it ideal for a variety of industrial applications. Unlike traditional synthetic fibers like glass or carbon fiber, basalt fiber is made by melting basalt rock at high temperatures and extruding the resulting molten material into fibers. These fibers are known for their excellent thermal resistance, high tensile strength, and durability, as well as being environmentally friendly, non-toxic, and highly resistant to corrosion and chemicals. Basalt fiber is used in a wide range of applications, including construction, automotive, aerospace, and infrastructure. Its unique properties allow for the production of lightweight, strong, and corrosion-resistant materials, making it an increasingly popular choice for industries seeking sustainable and high-performance alternatives to traditional fibers.

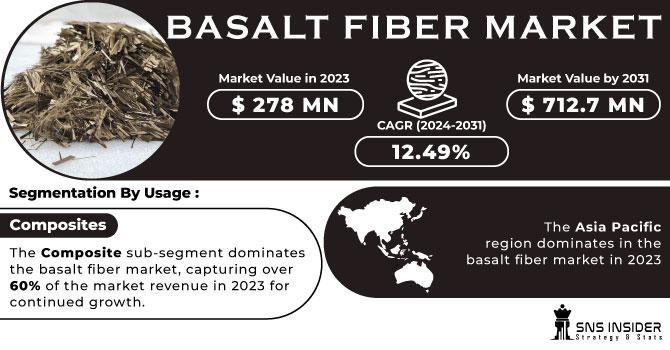

The Basalt Fiber Market Size was esteemed at USD 278 million out of 2023 and is supposed to arrive at USD 712.7 million by 2031, and develop at a CAGR of 12.49% over the forecast period 2024-2031.

Future Scope

The future scope of basalt fiber is extremely promising, driven by its superior characteristics and the growing demand for eco-friendly materials across industries. As sustainability becomes a key focus in manufacturing and construction, basalt fiber’s natural composition and environmental benefits position it as an attractive alternative to other materials like glass fiber and carbon fiber. The material's resistance to extreme temperatures, corrosive environments, and its ability to maintain structural integrity in harsh conditions further enhances its potential for use in sectors such as marine, oil and gas, and infrastructure. Additionally, as manufacturing processes improve and the availability of basalt fiber increases, the cost of production is expected to decrease, which will make it more accessible for wider use in applications ranging from automotive parts to wind turbines. With ongoing innovations in basalt fiber composites and the increasing adoption of sustainable building materials, basalt fiber is poised to play a significant role in the global shift toward green technologies and eco-conscious manufacturing.

Emerging Trends

The basalt fiber market is experiencing several emerging trends that are shaping its future growth. One of the key trends is the increasing demand for sustainable and eco-friendly materials, which is driving the adoption of basalt fiber in construction, automotive, and infrastructure projects. Basalt fiber’s natural composition and minimal environmental impact during production make it an appealing choice for green construction initiatives and sustainable product design. Another trend is the growing use of basalt fiber in composite materials. When combined with resins and other materials, basalt fiber enhances the mechanical properties of the composites, making them suitable for high-performance applications in industries like aerospace and automotive. Additionally, the development of basalt fiber-reinforced concrete is gaining momentum, particularly in the construction industry, due to its ability to improve the strength, durability, and resistance to corrosion in concrete structures. The increasing focus on renewable energy is also influencing the demand for basalt fiber, as it is being used in the manufacturing of wind turbine blades, where its lightweight and high-strength characteristics are highly valued.

Drivers

Several factors are driving the growth of the basalt fiber market. The primary driver is the increasing demand for lightweight and high-strength materials that can improve the performance and efficiency of products in industries such as automotive, aerospace, and construction. Basalt fiber offers a compelling alternative to traditional materials, providing enhanced durability, corrosion resistance, and thermal stability, all of which are critical for applications in extreme environments. Furthermore, the push for sustainability and eco-friendly manufacturing practices is a significant factor contributing to the rise of basalt fiber. With its low environmental impact during production and its recyclability, basalt fiber meets the growing need for sustainable solutions in construction, infrastructure, and other industries. The growing focus on renewable energy sources and the need for high-performance materials in wind energy applications is also driving the demand for basalt fiber, particularly for use in wind turbine blades and other renewable energy components.

Restraints

Despite its promising potential, the basalt fiber market faces some challenges that could limit its widespread adoption. One of the primary constraints is the relatively high cost of basalt fiber production, which remains higher compared to traditional materials like glass fiber. This cost disparity may limit its use in price-sensitive applications, particularly in regions where cost-efficiency is a major consideration. Additionally, while basalt fiber is gaining popularity, its production capacity and availability are still limited compared to more established materials like glass and carbon fibers. This limitation in supply could hinder the material’s widespread adoption across industries. There are also challenges related to the standardization of basalt fiber products and the lack of awareness about its advantages in certain industries, which may slow its uptake. However, as production techniques improve and economies of scale are realized, these challenges are expected to diminish.

Key Points

· Basalt fiber is a sustainable, high-performance material made from volcanic rock, known for its exceptional strength, corrosion resistance, and heat resistance.

· It is gaining traction in industries such as construction, automotive, aerospace, and infrastructure due to its lightweight properties and eco-friendly advantages.

· Emerging trends include its use in composite materials, reinforced concrete, and renewable energy applications, particularly in wind turbine blades.

· Key drivers include the demand for lightweight, durable materials, the shift toward sustainable manufacturing, and the growing focus on renewable energy.

· Challenges include the higher cost of production compared to traditional fibers, limited production capacity, and the need for greater industry awareness.

As the world moves toward greener and more sustainable solutions, basalt fiber’s unique properties and environmental benefits make it a key material for industries aiming to reduce their ecological footprints. With ongoing advancements in production techniques and expanding applications across various sectors, basalt fiber is set to become an increasingly vital material in the global push for more sustainable manufacturing and construction practices.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/2553

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness