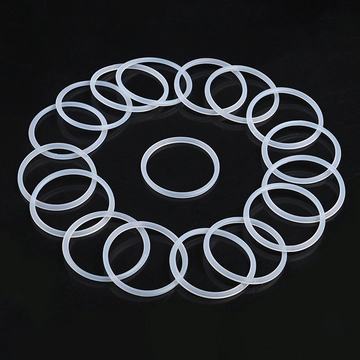

An Overview of Silicone Seal Rings: Properties and Applications

Silicone seal rings are essential components used in various industries due to their unique properties. These rings are made from silicone rubber, which is known for its flexibility, durability, and resistance to extreme temperatures. Silicone seal rings are designed to provide effective silicone seal ring in different applications. This article provides an overview of the properties and applications of silicone seal rings.

Properties of Silicone Seal Rings

Silicone seal rings possess several beneficial properties. One of the most notable characteristics is their excellent temperature resistance. Silicone can withstand a wide range of temperatures, from -60°C to 200°C. This makes silicone seal rings suitable for applications in extreme environments. Additionally, silicone is resistant to UV radiation and ozone, ensuring longevity and reliability.

Chemical Resistance

Another important property of silicone seal rings is their chemical resistance. Silicone rubber does not react with many chemicals, making it ideal for use in various industries. These seal rings can withstand exposure to oils, fuels, and solvents without degrading. This chemical stability is crucial for applications in automotive, aerospace, and chemical processing industries.

Flexibility and Compression Set

Silicone seal rings are known for their flexibility. This property allows them to conform to different surfaces, providing a tight seal. The compression set of silicone is low, meaning that the rings maintain their shape and sealing ability over time. This ensures that they can effectively prevent leaks and maintain pressure in various applications.

Applications in Automotive Industry

Silicone seal rings are widely used in the automotive industry. They are commonly found in engines, transmissions, and fuel systems. The ability of silicone to withstand high temperatures and resist chemical exposure makes it an ideal choice for sealing applications in vehicles. Silicone seal rings help prevent leaks and ensure the efficient operation of automotive systems.

Use in Aerospace Applications

In the aerospace industry, silicone seal rings play a critical role. They are used in aircraft engines, fuel systems, and hydraulic systems. The extreme temperature resistance of silicone is essential for maintaining performance in high-altitude environments. Silicone seal rings provide reliable sealing solutions that enhance the safety and efficiency of aerospace operations.

Applications in Food and Beverage Industry

The food and beverage industry also benefits from silicone seal rings. These rings are used in food processing equipment, packaging, and storage containers. Silicone is non-toxic and compliant with food safety regulations, making it a safe choice for food applications. The ability to withstand high temperatures allows silicone seal rings to be used in sterilization processes.

Use in Medical Devices

Silicone seal rings are crucial in the medical field. They are used in various medical devices, including syringes, IV bags, and surgical instruments. The biocompatibility of silicone ensures that it does not react with body fluids or tissues. Silicone seal rings help maintain sterile environments and prevent contamination in medical applications.

Applications in Electronics

In the electronics industry, silicone seal rings are used for sealing and protecting sensitive components. They provide moisture and dust resistance, ensuring the longevity of electronic devices. Silicone seal rings are commonly found in connectors, enclosures, and circuit boards. Their flexibility and durability make them ideal for use in various electronic applications.

Benefits of Using Silicone Seal Rings

The benefits of using silicone seal rings are numerous. Their temperature and chemical resistance make them suitable for a wide range of applications. Silicone seal rings are also easy to install and maintain. Their flexibility allows for effective sealing, reducing the risk of leaks and failures. These advantages contribute to the overall efficiency and reliability of systems that utilize silicone seal rings.

Challenges and Considerations

Despite their many advantages, there are challenges associated with silicone seal rings. One concern is the potential for silicone to swell when exposed to certain chemicals. Manufacturers must ensure that the silicone used in seal rings is compatible with the specific substances it will encounter. Additionally, proper installation is crucial to ensure optimal sealing performance.

Future Trends in Silicone Seal Rings

The future of silicone seal rings looks promising. Advances in material science are leading to the development of new silicone formulations that enhance performance. Researchers are exploring ways to improve the durability and chemical resistance of silicone seal rings. These innovations will expand the applications of silicone seal rings in various industries.

Conclusion

In conclusion, silicone seal rings are vital components in many industries. Their unique properties, such as temperature resistance, chemical stability, and flexibility, make them suitable for a wide range of applications. From automotive to medical devices, silicone seal rings provide effective sealing solutions that enhance performance and reliability. As technology continues to advance, the future of silicone seal rings will likely bring even more innovative applications

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness