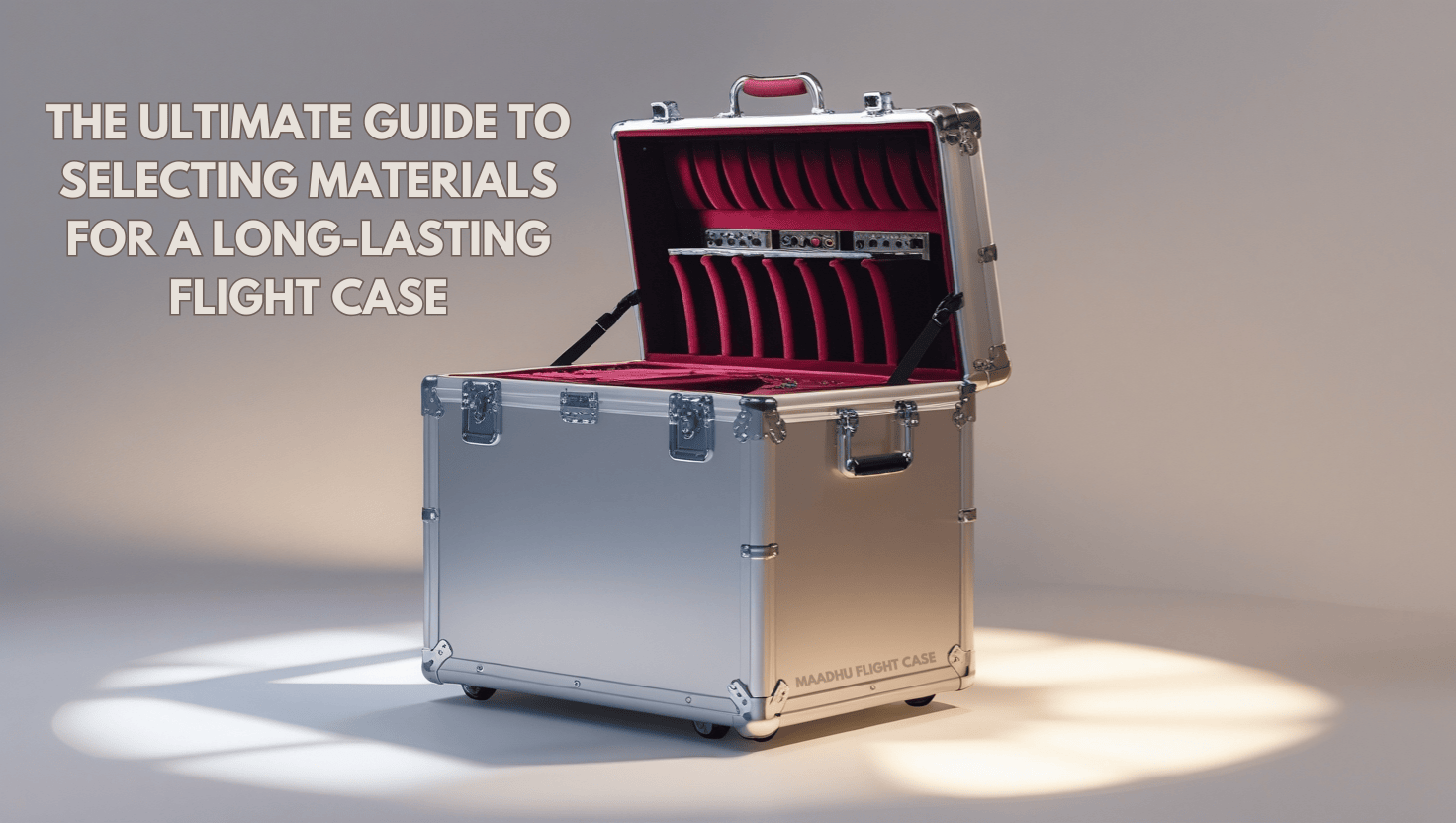

The Ultimate Guide to Selecting Materials for a Long-Lasting Flight Case

When it comes to protecting your equipment during transport, selecting the right materials for your flight case is critical. Flight cases are designed to provide durability, safety, and functionality, ensuring that your sensitive equipment remains intact no matter the conditions. Whether you’re transporting valuable musical instruments, camera gear, or industrial tools, the flight case you choose must offer the right protection. This guide will walk you through the key factors to consider when selecting materials for a long-lasting flight case, covering various materials, their pros and cons, and what makes them suitable for different applications.

What Is a Flight Case and Why Is It Important?

A flight case is a hard, protective container used to store and transport delicate or expensive equipment, often used in industries like music, film, electronics, and manufacturing. These cases are designed to withstand the rough handling associated with shipping, flights, and other forms of travel. The right choice of materials for your flight case will determine its longevity, weight, and the level of protection it provides.

When selecting materials, it’s important to balance factors like strength, weight, weather resistance, and ease of handling. The perfect flight case should safeguard your equipment from shocks, temperature changes, moisture, and dirt while ensuring it’s not overly cumbersome.

Key Factors to Consider When Selecting Materials for a Flight Case

Before diving into the specific materials, let’s first examine the essential factors that will guide your decision:

-

Durability and Strength: Flight cases need to withstand rough handling during transport, so the material should be tough enough to protect against external impacts.

-

Weight: A heavy flight case may seem sturdy, but it could increase transportation costs and be difficult to move around.

-

Weather Resistance: The case should be resistant to moisture, dust, and temperature changes to protect your gear in various environments.

-

Customizability: The material should allow for easy customization to meet specific needs, whether it’s for padding, compartments, or external accessories.

-

Cost: Budget plays a role in the material selection, so it’s crucial to choose a material that balances cost with performance.

Now, let’s take a deeper look at the materials that make up the best flight cases.

1. Plywood: The Classic Choice

Plywood has been the traditional material for flight cases for many years, offering a solid blend of strength and flexibility. It consists of layers of wood veneer glued together, making it incredibly sturdy.

Pros of Plywood:

-

Strong and Durable: Plywood provides excellent protection from shocks and impacts, making it a long-lasting option for flight cases.

-

Versatile: It can be easily customized with different types of finishes, colors, and hardware.

-

Cost-Effective: Plywood is typically more affordable than some other materials, offering great value for money.

Cons of Plywood:

-

Heavy: While durable, plywood can be relatively heavy, making it less suitable for transporting lightweight equipment.

-

Moisture Sensitivity: If exposed to moisture over time, plywood can warp and deteriorate unless treated properly.

Plywood is ideal for industries like music and live events, where heavy-duty protection is required, and weight isn’t the main concern.

2. ABS Plastic: Lightweight and Impact-Resistant

ABS plastic is a popular alternative to plywood, offering a lightweight yet strong material that can absorb shock effectively. This material is often used for cases that need to be portable but still require substantial protection.

Pros of ABS Plastic:

-

Lightweight: ABS plastic is much lighter than plywood, which is a significant advantage if you need to transport cases over long distances or frequently.

-

Durable and Impact-Resistant: ABS plastic is highly resistant to impact and can absorb shocks better than some other materials.

-

Weatherproof: It has strong resistance to moisture and is less likely to warp or degrade in wet conditions.

Cons of ABS Plastic:

-

Less Customizable: While ABS can be molded, it may not offer as much customization as wood-based materials.

-

Potential Scratching: ABS can scratch and scuff more easily than some other options, which may affect the aesthetic appeal.

For industries that prioritize portability, such as photography or film production, ABS plastic cases offer the perfect balance of strength and lightweight design.

3. Aluminum: The Premium Choice

Aluminum flight cases are known for their sleek appearance, superior durability, and long lifespan. These cases often come with a rugged exterior that resists corrosion, making them ideal for tough environments.

Pros of Aluminum:

-

Highly Durable: Aluminum is a lightweight yet incredibly strong material that offers excellent protection against impacts, scratches, and corrosion.

-

Corrosion-Resistant: Aluminum resists rust, making it an ideal material for cases exposed to various environmental conditions.

-

Professional Appearance: Aluminum flight cases often have a polished, clean look, making them ideal for high-end gear in industries like entertainment or electronics.

Cons of Aluminum:

-

Expensive: Aluminum cases are generally pricier than plywood or ABS plastic, so they may not be the best choice for those on a strict budget.

-

Can Dent: While aluminum is resistant to rust, it can dent or get damaged more easily under extreme impacts.

Aluminum flight cases are widely used in industries like aerospace, professional audio, and medical equipment transport, where durability, professional appearance, and resistance to the elements are essential.

4. Plastic Laminates and Composite Materials: The Modern Solution

For those looking for a high-performance option, composite materials and plastic laminates can be an excellent choice. These materials combine various elements, including fiberglass, plastic, and even foam, to create ultra-strong, lightweight flight cases.

Pros of Laminates and Composites:

-

Lightweight and Tough: These cases offer excellent protection without adding too much weight to your load.

-

Weather-Resistant: Composite materials are often resistant to the effects of moisture, temperature changes, and UV radiation.

-

Customizable: You can choose from different finishes, colors, and patterns, making these cases aesthetically appealing.

Cons of Laminates and Composites:

-

Price: Similar to aluminum, composite cases can be on the expensive side due to their manufacturing process and advanced materials.

These materials are ideal for industries that need both durability and a modern, attractive appearance, such as high-tech electronics, media production, and medical device transportation.

5. Foam Inserts and Padding: The Final Touch

No matter the outer material you choose, the foam inserts and padding inside your flight case are just as important. Foam can be customized to fit the exact shape and dimensions of your equipment, providing cushioning and further protection from damage during transport.

Conclusion: Choosing the Right Material for Your Flight Case

When selecting materials for your flight case, it’s essential to prioritize durability, weight, weather resistance, and cost. The material you choose will depend on the type of equipment you need to protect and the conditions in which it will be transported. Whether you opt for plywood, ABS plastic, aluminum, or composite materials, ensuring that your flight case is sturdy, secure, and long-lasting is key to protecting your valuable gear.

Frequently Asked Questions

1. What is the most durable material for a flight case? Aluminum is often regarded as the most durable material due to its strength, corrosion resistance, and ability to withstand heavy impacts.

2. Are ABS plastic cases a good choice for travel? Yes, ABS plastic is lightweight, durable, and resistant to weather conditions, making it an excellent option for frequent travelers or industries that require portability.

3. Can I customize the interior of my flight case? Absolutely! Many flight case manufacturers offer customizable foam inserts and padding to protect your equipment securely, ensuring a perfect fit for your gear.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness