The Thickness Gauge from Tool.com is an essential tool for professionals who need to measure the thickness of various materials with precision. These devices are widely used across industries such as engineering, construction, and manufacturing, where material specifications are critical to the success and safety of projects.

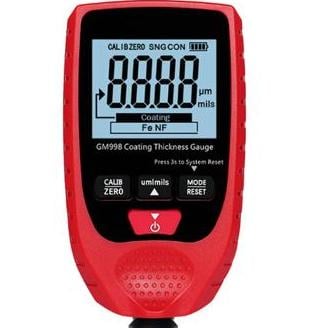

Tool.com offers a range of thickness gauges, each designed for specific applications. Ultrasonic Thickness Gauges use ultrasonic waves to measure the thickness of materials like metals, plastics, and composites without causing any damage. They are particularly useful for situations where only single-sided access to the material is available. Coating Thickness Gauges are ideal for determining the thickness of coatings on various substrates, utilizing magnetic induction or eddy current technology depending on the material type. For those needing a compact and portable solution, Mini Thickness Gauges are perfect for on-the-go measurements in tight spaces. Digital and LCD Thickness Gauges provide clear, easy-to-read measurements and often include features like data storage and high/low measurement limit alerts.

Using a thickness gauge from Tool.com is a simple process. First, ensure the surface is clean and free of any debris that could affect the reading. Some models require calibration before use, so follow the manufacturer's instructions to ensure accurate measurements. For ultrasonic gauges, apply a couplant like gel to the surface and place the probe against it. Mechanical jaw gauges require opening the jaws, positioning them around the material, and closing to take the measurement. The gauge will display the thickness measurement, which should be read according to the unit indicated.

Advanced models allow for data storage and analysis, which is useful for quality control and monitoring material conditions over time. After use, it's important to keep the gauge clean and store it properly to ensure its longevity and accuracy.

Thickness gauges from Tool.com are used in a variety of applications, such as mechanical engineering, metal fabrication, vehicle restoration, and quality control. They provide non-destructive testing capabilities, ensuring materials remain intact while their thickness is measured. The high level of accuracy and digital/LCD display features make these gauges indispensable for professionals who require precise material thickness data.

Tool.com's Thickness Gauges are versatile tools that cater to a wide range of thickness measurement needs. Their accuracy, ease of use, and durability make them valuable assets in any professional setting where precise thickness measurements are required.

Tool.com offers a range of thickness gauges, each designed for specific applications. Ultrasonic Thickness Gauges use ultrasonic waves to measure the thickness of materials like metals, plastics, and composites without causing any damage. They are particularly useful for situations where only single-sided access to the material is available. Coating Thickness Gauges are ideal for determining the thickness of coatings on various substrates, utilizing magnetic induction or eddy current technology depending on the material type. For those needing a compact and portable solution, Mini Thickness Gauges are perfect for on-the-go measurements in tight spaces. Digital and LCD Thickness Gauges provide clear, easy-to-read measurements and often include features like data storage and high/low measurement limit alerts.

Using a thickness gauge from Tool.com is a simple process. First, ensure the surface is clean and free of any debris that could affect the reading. Some models require calibration before use, so follow the manufacturer's instructions to ensure accurate measurements. For ultrasonic gauges, apply a couplant like gel to the surface and place the probe against it. Mechanical jaw gauges require opening the jaws, positioning them around the material, and closing to take the measurement. The gauge will display the thickness measurement, which should be read according to the unit indicated.

Advanced models allow for data storage and analysis, which is useful for quality control and monitoring material conditions over time. After use, it's important to keep the gauge clean and store it properly to ensure its longevity and accuracy.

Thickness gauges from Tool.com are used in a variety of applications, such as mechanical engineering, metal fabrication, vehicle restoration, and quality control. They provide non-destructive testing capabilities, ensuring materials remain intact while their thickness is measured. The high level of accuracy and digital/LCD display features make these gauges indispensable for professionals who require precise material thickness data.

Tool.com's Thickness Gauges are versatile tools that cater to a wide range of thickness measurement needs. Their accuracy, ease of use, and durability make them valuable assets in any professional setting where precise thickness measurements are required.

Recent Updates

-

Please log in to like, share and comment!

-

0 Comments 0 Shares 83 Views 0 Reviews

More Stories