Aluminum Nitride Market Top Companies, New Technology, Demand and Opportunities (2024-2032)

Aluminum nitride (AlN) is a highly thermally conductive ceramic material with excellent electrical insulation properties. Its unique combination of high thermal conductivity, low dielectric constant, and superior mechanical strength makes it a critical material in advanced electronics, power semiconductors, and aerospace applications. Due to its excellent resistance to thermal shock and chemical stability, aluminum nitride is widely used in heat sinks, substrates, and electronic packaging solutions. As industries demand high-performance materials for miniaturization and thermal management, AlN continues to gain prominence in semiconductor manufacturing, optoelectronics, and high-frequency communication systems.

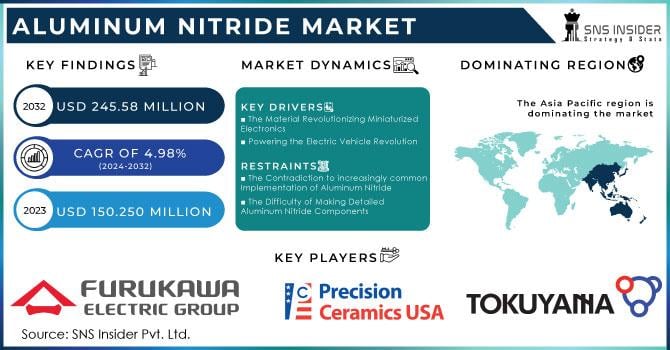

The Aluminum Nitride Market was Valued at USD 150.250 Million in 2023 and is now anticipated to grow to USD 245.58 Million by 2032, displaying a compound annual growth rate (CAGR) 4.98% of during the forecast Period 2024 - 2032.

Future Scope

The future of aluminum nitride is driven by its increasing adoption in high-power and high-frequency electronic devices. As demand for efficient thermal management solutions rises in power electronics, 5G infrastructure, and electric vehicles (EVs), AlN substrates and coatings are expected to play a pivotal role in improving device performance and reliability. Additionally, ongoing research into enhancing the synthesis and fabrication techniques of AlN-based components is expected to lower production costs and expand its commercial applications. Innovations in additive manufacturing and nanotechnology could further enhance the material’s properties, paving the way for next-generation applications in quantum computing and photonic devices.

Emerging Trends

Several key trends are shaping the aluminum nitride market. The development of ultra-thin and high-purity AlN substrates is supporting advancements in microelectronics and semiconductor packaging. The increasing focus on gallium nitride (GaN)-on-AlN technology is enabling the production of high-power RF and microwave devices for telecommunications and defense applications. Additionally, the integration of AlN in LED lighting systems and high-temperature sensors is gaining traction. The push for environmentally sustainable and energy-efficient materials is also leading to advancements in AlN recycling and reprocessing techniques.

Drivers

The growing demand for high-performance electronic components is a primary driver for aluminum nitride adoption. The expansion of the power semiconductor industry, particularly for EVs and renewable energy systems, is fueling demand for AlN-based heat dissipation solutions. The rise of 5G networks and next-generation communication technologies is boosting the need for AlN substrates in RF and microwave applications. Additionally, advancements in semiconductor fabrication techniques are enhancing the manufacturability and cost-effectiveness of AlN-based components, further driving market growth.

Restraints

Despite its advantages, aluminum nitride faces certain challenges that limit its widespread adoption. The high cost of production, due to complex synthesis and processing methods, remains a significant barrier. Limited availability of high-purity raw materials and the intricate fabrication techniques required for AlN substrates also contribute to higher costs. Additionally, competition from alternative materials such as alumina (Al₂O₃) and silicon carbide (SiC) in some applications may restrict its market penetration. Further, technical challenges in integrating AlN into existing semiconductor manufacturing processes pose hurdles for large-scale adoption.

Key Points

· Aluminum nitride is a high-performance ceramic known for its exceptional thermal conductivity and electrical insulation.

· It is widely used in power electronics, semiconductor packaging, and high-frequency communication systems.

· The growing demand for efficient thermal management solutions is driving AlN adoption in 5G, EVs, and renewable energy applications.

· Advancements in AlN fabrication and synthesis techniques are expected to enhance cost-effectiveness and scalability.

· Challenges include high production costs, material availability, and competition from alternative ceramic materials.

Conclusion

Aluminum nitride continues to gain importance as industries seek advanced materials with superior thermal and electrical properties. Its role in power electronics, semiconductor manufacturing, and high-frequency applications is expected to expand as technological advancements improve its cost efficiency and performance. While challenges such as high production costs persist, ongoing research and innovation in AlN processing will drive its adoption across emerging high-tech industries, solidifying its place as a critical material in the future of electronics and advanced manufacturing.

Read Full Report @ https://www.snsinsider.com/reports/aluminum-nitride-market-1419

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness