UV Stabilizers Market Size, Share, Industry Analysis and Forecast 2024-2032

UV stabilizers are essential additives used to protect materials from the damaging effects of ultraviolet (UV) radiation. These stabilizers help prevent the degradation of polymers, plastics, and other materials exposed to sunlight, ensuring their longevity and maintaining their physical properties. UV stabilizers function by absorbing or reflecting harmful UV rays, which can cause fading, brittleness, and overall deterioration of materials. Widely used in industries such as automotive, construction, packaging, and textiles, UV stabilizers are crucial for extending the life and performance of products exposed to outdoor elements. Their importance continues to grow as demand for durable, long-lasting materials increases across various sectors.

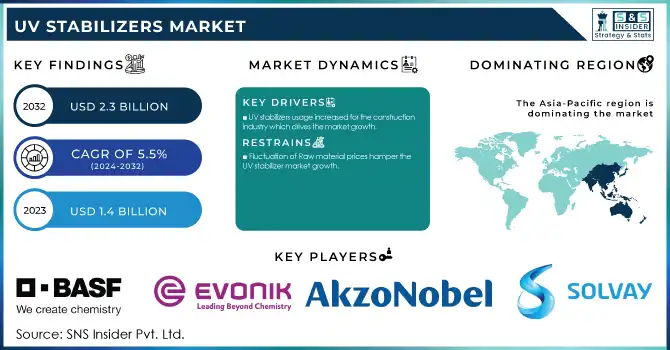

The UV Stabilizers Market Size was USD 1.4 billion in 2023 and is expected to reach USD 2.3 billion by 2032 and grow at a CAGR of 5.5% over the forecast period of 2024-2032.

Future Scope

The future of UV stabilizers looks promising, driven by increasing global demand for materials that can withstand harsh environmental conditions. As industries place greater emphasis on sustainability, the development of eco-friendly UV stabilizers, particularly those derived from renewable sources, is expected to gain momentum. Innovations in UV stabilizer technology are focusing on improving the efficiency of these additives, providing longer-lasting protection with lower concentrations, and enhancing their compatibility with a broader range of materials. With the growing need for outdoor and long-life products, such as automotive parts, solar panels, and building materials, the demand for UV stabilizers is projected to rise significantly.

Emerging Trends

One of the key emerging trends in the UV stabilizers market is the increasing use of hybrid stabilizers that combine the benefits of multiple additives, such as antioxidants and light stabilizers, to offer enhanced protection. Additionally, there is a notable shift toward bio-based UV stabilizers, driven by the growing demand for sustainable and non-toxic products. In the automotive sector, UV stabilizers are being integrated into coatings and components to improve the weather resistance of vehicles, contributing to longer-lasting paint and reduced fading. Furthermore, the growing trend of using UV stabilizers in the manufacturing of packaging materials, particularly those used in food and beverages, is expanding as brands focus on improving product shelf life and visual appeal.

Drivers

The UV stabilizers market is being driven by the rapid expansion of industries that rely on durable, weather-resistant materials. With the increasing use of plastics and polymers in outdoor applications such as construction, packaging, and automotive manufacturing, the demand for UV stabilizers has surged. The growing trend toward sustainable products is also contributing to the market’s expansion, as consumers and manufacturers alike seek materials that offer longer lifespans with less environmental impact. Additionally, UV stabilizers are becoming an integral part of industries like agriculture, where they help protect materials such as greenhouse films and irrigation systems from UV degradation, supporting more efficient crop production and resource management.

Restraints

Despite their advantages, the UV stabilizers market faces several challenges. One of the primary constraints is the potential environmental impact of some traditional UV stabilizers, which may be toxic or non-biodegradable. This has led to growing regulatory pressure for manufacturers to develop safer and more eco-friendly alternatives. Furthermore, the high cost of some advanced UV stabilizers, particularly those with enhanced performance properties, can be a barrier to adoption, especially in cost-sensitive markets. The complexity of formulating UV stabilizers that are compatible with various materials, particularly when balancing cost, performance, and environmental concerns, is another challenge for the industry.

Key Points

· UV stabilizers protect materials from the harmful effects of UV radiation, enhancing their durability and lifespan.

· Widely used in industries such as automotive, construction, packaging, and textiles.

· Emerging trends include hybrid stabilizers, bio-based options, and expanded use in automotive and packaging sectors.

· Drivers include the growing demand for durable outdoor materials and the shift toward sustainable products.

· Challenges include environmental concerns and the high cost of advanced stabilizers.

Conclusion

UV stabilizers play a crucial role in preserving the performance and appearance of materials exposed to sunlight, ensuring their longevity and functionality. As industries continue to focus on sustainability and durability, the demand for advanced UV stabilizers is expected to increase. Innovations in bio-based and hybrid stabilizers are paving the way for safer, more efficient solutions that meet environmental and performance standards. Although challenges such as regulatory pressures and cost constraints remain, the future of UV stabilizers is bright, with expanding applications across various industries. As these stabilizers evolve to meet modern demands, they will continue to be an indispensable component in the production of long-lasting and reliable materials.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/2017

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness