Polyolefin Pipes Market Current Trends, Technology and Industry Analysis 2032

Polyolefin pipes, made from polymers such as polyethylene (PE) and polypropylene (PP), are increasingly being used in plumbing, infrastructure, and industrial applications due to their exceptional durability, resistance to corrosion, and ease of installation. These pipes are lightweight, flexible, and have a long service life, making them a preferred choice for both residential and commercial projects. Polyolefin pipes are ideal for water distribution systems, sewage systems, and gas pipelines, offering superior performance in various environments. Their versatility, combined with cost-effectiveness and sustainability benefits, positions them as a key solution for modern construction and infrastructure development.

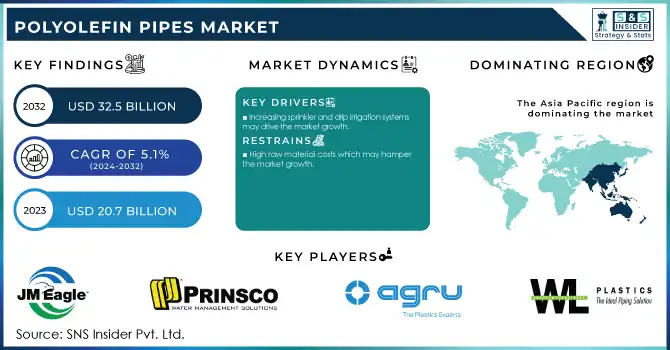

The Polyolefin Pipes Market Size was USD 20.7 billion in 2023 and is expected to reach USD 32.5 billion by 2032 and grow at a CAGR of 5.1% over the forecast period of 2024-2032.

Future Scope

The future of polyolefin pipes is promising, driven by advancements in material technology and an increased demand for sustainable solutions in the construction and utility sectors. Research is focusing on enhancing the properties of polyolefin pipes, such as improving their resistance to high temperatures, chemicals, and ultraviolet (UV) radiation. Furthermore, the integration of smart technologies, such as sensors for leak detection and system monitoring, is expected to drive innovation in this field. As global infrastructure development continues to rise, polyolefin pipes are projected to witness substantial growth, particularly in emerging markets where water distribution and sewage systems are rapidly expanding.

Emerging Trends

One of the key emerging trends in the polyolefin pipes market is the development of multi-layered pipes that combine the benefits of different materials, such as a combination of PE with aluminum or other reinforcing materials, to enhance their mechanical properties. Additionally, the increasing emphasis on sustainable construction practices is pushing for the use of recycled and recyclable polyolefin materials in pipe production. There is also a rising trend toward the use of polyolefin pipes in challenging applications, such as those requiring resistance to aggressive chemicals or extreme temperatures, thanks to ongoing improvements in their chemical and heat resistance.

Drivers

Polyolefin pipes are gaining widespread adoption due to their numerous advantages, including their resistance to corrosion, which ensures a longer lifespan compared to traditional metal pipes. Their lightweight nature and ease of installation reduce labor costs and installation time, making them a cost-effective option for a wide range of applications. The growing demand for efficient water management systems, particularly in regions facing water scarcity, is driving the use of polyolefin pipes in water distribution and irrigation systems. Additionally, their resistance to scale buildup and biofouling makes them ideal for use in sewage and industrial piping systems.

Restraints

Despite their many benefits, the polyolefin pipes market faces some challenges. These pipes can be vulnerable to damage from UV radiation over time, which can weaken the material if not properly protected. The initial cost of polyolefin pipes, particularly for high-end applications, may be higher than traditional materials like PVC and steel, which can deter some consumers. Additionally, while polyolefin pipes are highly resistant to corrosion, they may not be suitable for all applications, such as those requiring extreme pressure resistance or those exposed to specific chemical environments.

Key Points

· Polyolefin pipes are made from polymers like polyethylene (PE) and polypropylene (PP), offering corrosion resistance and durability.

· They are widely used in water distribution, sewage systems, and industrial piping.

· Emerging trends include multi-layered pipes and the use of recycled materials in production.

· Key drivers include cost-effectiveness, ease of installation, and demand for efficient water management.

· Challenges include vulnerability to UV radiation, higher initial costs, and limitations in extreme applications.

Conclusion

Polyolefin pipes are transforming the way modern infrastructure and plumbing systems are designed and implemented. With their superior resistance to corrosion, ease of installation, and cost-effectiveness, they are becoming the material of choice for various applications in the construction and utilities sectors. As technological advancements continue to improve the material properties and sustainability of polyolefin pipes, their market presence is expected to expand significantly. While challenges such as UV degradation and initial cost remain, ongoing innovations promise to enhance their performance and extend their use in more specialized applications. Polyolefin pipes are set to play a central role in the development of resilient, sustainable infrastructure in the years to come.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/2014

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness