Industrial Nitrogen Generator Market by Top Key Players, Types, Applications and Future Forecast to 2032

Industrial nitrogen generators have revolutionized the way businesses obtain a reliable and on-demand supply of nitrogen gas. These systems, leveraging technologies such as Pressure Swing Adsorption (PSA) and membrane separation, provide a cost-effective alternative to traditional nitrogen delivery methods like gas cylinders or liquid nitrogen tanks. Nitrogen generators are extensively used in industries such as food and beverage, electronics, pharmaceuticals, and chemical processing, where purity, safety, and efficiency are paramount. By eliminating dependency on external suppliers, these systems offer enhanced control over production processes while minimizing operational costs.

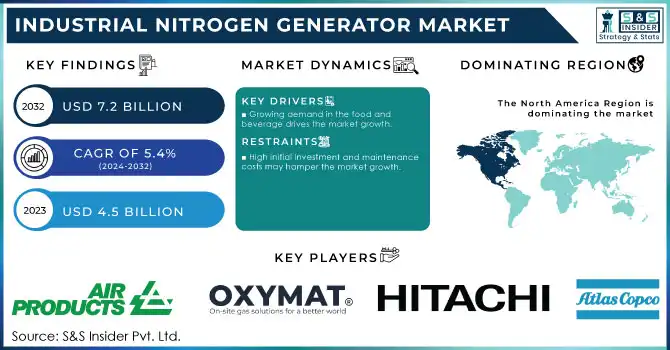

The Industrial Nitrogen Generator Market Size was USD 4.5 Billion in 2023 and is expected to reach USD 7.2 Billion by 2032 and grow at a CAGR of 5.4% over the forecast period of 2024-2032.

Future Scope

The future of industrial nitrogen generators is defined by advancements in energy efficiency and the integration of smart monitoring systems. As industries increasingly prioritize sustainability, nitrogen generators with reduced energy consumption and carbon footprints will gain traction. Emerging applications in additive manufacturing, 3D printing, and renewable energy sectors are expected to expand the scope of nitrogen generator usage. Additionally, modular and portable designs are likely to cater to small-scale businesses and remote operations, broadening their adoption. With continuous technological innovation, nitrogen generators are set to become more versatile and environmentally friendly, addressing the evolving demands of industrial applications.

Emerging Trends

The industrial nitrogen generator market is witnessing a rise in innovations tailored to specific industry needs. Compact and modular systems that allow scalability are gaining popularity among small and mid-sized enterprises. The integration of IoT-enabled sensors for real-time monitoring of gas purity and system performance is enhancing operational reliability. Renewable energy-powered nitrogen generators are also emerging, aligning with the global push for green energy solutions. Moreover, hybrid nitrogen generators combining PSA and membrane technologies are being developed to provide enhanced flexibility and efficiency.

Drivers

Several factors are driving the adoption of industrial nitrogen generators, including the growing demand for uninterrupted nitrogen supply in critical industries such as healthcare, food packaging, and chemical processing. The rising awareness of the operational and cost benefits of on-site nitrogen generation compared to traditional delivery methods is a significant growth driver. Environmental regulations mandating sustainable practices in industries are also pushing the adoption of energy-efficient nitrogen generators. Furthermore, the increasing penetration of advanced manufacturing technologies and the expansion of industries in developing economies are contributing to market growth.

Restraints

Despite their advantages, industrial nitrogen generators face challenges such as high initial capital investment and maintenance costs, which can deter small businesses from adopting these systems. The complexity of system design and the need for trained personnel for operation and troubleshooting also pose barriers. Additionally, ensuring consistent gas purity in certain high-precision applications requires specialized systems, which can add to the overall cost. Limited awareness of the long-term benefits of nitrogen generators in some regions further hinders market growth.

Key Points

· Industrial nitrogen generators provide an on-demand and cost-effective nitrogen supply.

· Technologies like Pressure Swing Adsorption (PSA) and membrane separation dominate the market.

· Growing applications in food packaging, electronics, pharmaceuticals, and renewable energy are driving demand.

· IoT-enabled systems and hybrid technologies are key trends enhancing efficiency and reliability.

· High upfront costs and maintenance requirements are significant market restraints.

Conclusion

Industrial nitrogen generators are transforming the landscape of nitrogen supply, offering industries a reliable, efficient, and sustainable solution. With advancements in technology and increasing emphasis on operational efficiency, these systems are becoming indispensable across a wide range of applications. Addressing cost and technical challenges will be critical to accelerating their adoption, particularly among small and mid-sized enterprises. As industries continue to evolve, nitrogen generators will remain a cornerstone in enabling seamless production processes and fostering sustainable industrial growth.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/1980

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness