Flue Gas Desulfurization System Market Size, Growth Rate, Industry Opportunities, and Forecast by 2032

Flue Gas Desulfurization (FGD) systems have emerged as a critical solution in mitigating air pollution caused by sulfur dioxide (SO₂) emissions. These systems are primarily employed in industrial facilities, power plants, and refineries to remove SO₂ from flue gases, ensuring compliance with stringent environmental regulations. FGD systems employ various methods, such as wet, dry, and semi-dry scrubbing, to neutralize harmful gases, offering an environmentally friendly approach to emission control. With increasing awareness of environmental degradation and its adverse effects, industries worldwide are adopting FGD systems to meet evolving air quality standards and achieve sustainability goals.

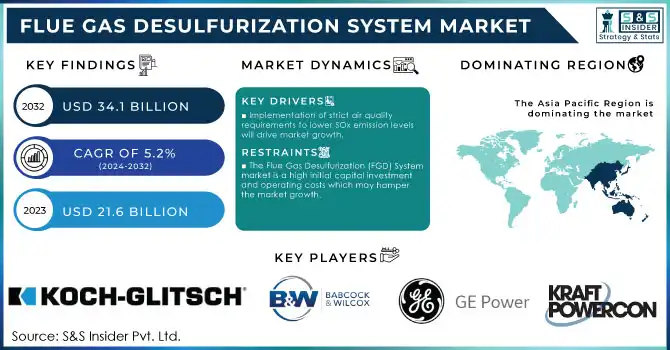

The Flue Gas Desulfurization System Market Size was USD 21.6 Billion in 2023 and is expected to reach USD 34.1 Billion by 2032 and grow at a CAGR of 5.2% over the forecast period of 2024-2032.

Future Scope

The future of FGD systems is poised for significant advancements driven by technological innovations and stricter environmental mandates. As industries transition toward decarbonization, the integration of FGD systems with carbon capture technologies presents a promising avenue for holistic emission control. Additionally, the rise of renewable energy sources and cleaner combustion technologies will reshape the demand and application scope of FGD systems. Emerging economies are anticipated to be key markets for FGD adoption as industrialization accelerates and governments enforce compliance with global emission norms. Research and development initiatives aimed at enhancing the efficiency and cost-effectiveness of these systems will further propel their adoption across sectors.

Emerging Trends

Advancements in FGD technology are focusing on optimizing system efficiency and reducing operational costs. The development of hybrid FGD systems combining wet and dry methods is gaining traction, offering enhanced flexibility and performance. Additionally, the use of advanced materials, such as corrosion-resistant alloys and novel sorbents, is enhancing the durability and effectiveness of these systems. Automation and digital monitoring technologies are also transforming FGD operations by enabling real-time tracking of emissions and predictive maintenance, thus improving reliability. Another notable trend is the recycling of byproducts, such as gypsum, which can be used in the construction industry, promoting a circular economy.

Drivers

The primary driver for the adoption of FGD systems is the enforcement of stringent environmental regulations aimed at reducing SO₂ emissions. Governments across the globe are mandating the installation of FGD systems in industries to combat air pollution and its detrimental health impacts. The rapid pace of industrialization and urbanization, especially in developing countries, has intensified the need for emission control solutions. Furthermore, the growing awareness of corporate social responsibility and sustainability initiatives among industries is spurring investments in FGD technology.

Restraints

Despite its critical role in emission control, the adoption of FGD systems faces several challenges. High initial installation costs and maintenance expenses often deter small and medium enterprises from adopting these solutions. The complex infrastructure requirements and energy-intensive operations of FGD systems pose additional constraints. Moreover, the disposal of waste generated during the desulfurization process, such as sludge and spent sorbents, presents environmental challenges that require careful management.

Key Points

· FGD systems remove sulfur dioxide (SO₂) from industrial flue gases to meet environmental regulations.

· Emerging technologies include hybrid FGD systems, advanced sorbents, and real-time monitoring solutions.

· Stricter emission norms and industrialization in developing economies are driving market growth.

· High costs and environmental concerns related to waste management are significant restraints.

· The recycling of byproducts like gypsum promotes sustainability in FGD operations.

Conclusion

Flue Gas Desulfurization systems are pivotal in achieving cleaner air and mitigating the environmental impact of industrial emissions. With evolving technologies and a global focus on sustainable practices, the FGD industry is set to witness robust growth. However, addressing cost and waste management challenges remains crucial for widespread adoption. As industries strive to align with stringent emission standards and sustainability goals, FGD systems will continue to play a vital role in shaping a cleaner, healthier future.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/1976

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness