CNC Machining Service: Revolutionizing Modern Manufacturing

In the ever-evolving world of manufacturing, precision and efficiency are crucial. As industries push for better performance and cost-effective production, CNC (Computer Numerical Control) machining services have emerged as a game-changer. CNC machining is a process that uses automated controls to operate machine tools, enabling the production of highly precise and complex parts. This article delves into the importance of CNC machining service, its benefits, types, and the industries that rely on it.

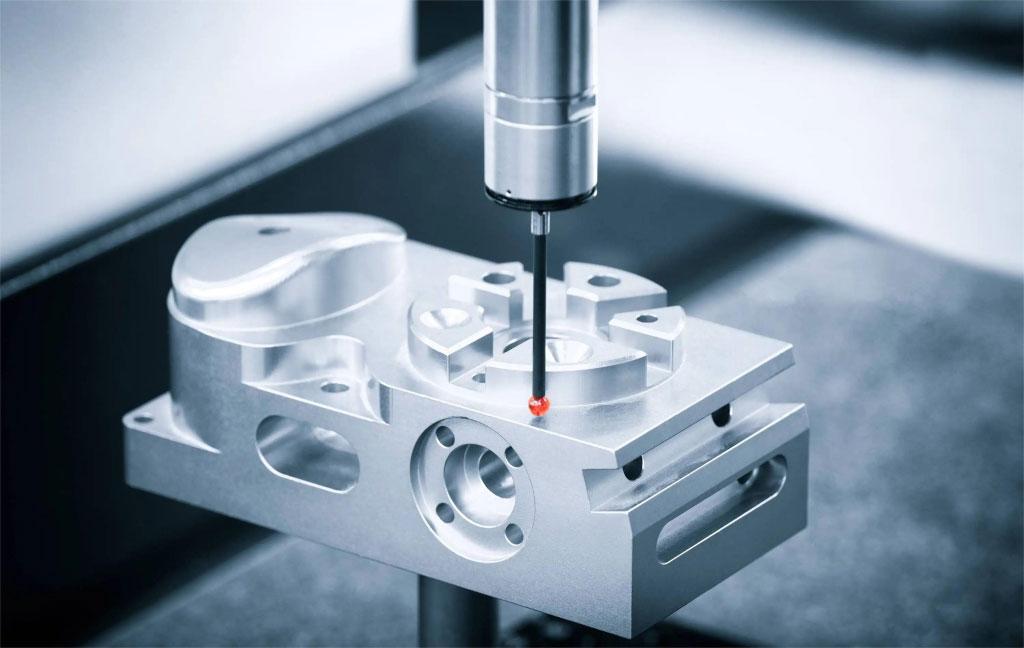

What is CNC Machining?

CNC machining refers to the use of computers to control machine tools in the manufacturing process. It can handle a variety of machines such as lathes, mills, routers, and grinders. The key advantage of CNC is that the process is automated, allowing for faster production times, increased precision, and reduced risk of human error.

The process starts with the creation of a 3D model or CAD (Computer-Aided Design) file of the part to be produced. This file is then converted into machine-readable code (G-code). The CNC machine follows this code to cut, shape, and finish materials with exceptional accuracy.

The Components of CNC Machining

CNC machining involves several components that work together to create the final product:

-

CNC Controller: The brain of the machine, the controller receives input from the operator and sends instructions to the machine tools. It interprets the CAD files into motion commands.

-

Machine Tools: These include equipment like CNC mills, lathes, and grinders. Each tool serves a specific function, such as drilling, cutting, and grinding, to shape the material as required.

-

Tooling: The physical tools used in CNC machining, including drills, mills, and cutters. These are interchangeable, enabling a range of tasks to be completed.

-

Material: The raw material, which could be metals, plastics, or composites, is placed into the machine for processing.

Types of CNC Machining Services

CNC machining services can be categorized based on the type of machine used and the specific manufacturing process. Here are the most common types:

1. CNC Milling

CNC milling involves using rotating cutting tools to remove material from a workpiece. The process is highly versatile and can be used to create flat surfaces, pockets, slots, and more complex features. CNC mills can operate on 3, 4, or 5 axes, depending on the machine's complexity.

2. CNC Turning

CNC turning involves rotating a workpiece while a stationary cutting tool is applied to it. It is typically used to create cylindrical parts, such as shafts, nuts, and bolts. The machine’s lathe can perform operations like drilling, boring, and threading.

3. CNC Routing

CNC routing uses high-speed rotary cutters to carve designs into materials like wood, plastic, and metal. It’s commonly used for large-scale production of complex shapes, often seen in the automotive and aerospace industries.

4. CNC Grinding

CNC grinding is a machining process that involves removing small amounts of material from a workpiece using a rotating abrasive wheel. It is ideal for finishing parts that require high precision and smooth surfaces.

5. CNC Electrical Discharge Machining (EDM)

EDM is used to cut or shape conductive materials by using electrical discharges. It's commonly employed to create intricate shapes, holes, and cavities that would be difficult to achieve through traditional machining.

6. CNC Laser Cutting

This method uses high-powered lasers to cut or engrave materials. It is ideal for cutting thin materials like sheet metal and plastics with high precision.

Advantages of CNC Machining Services

CNC machining offers several advantages over traditional manual methods:

1. Precision and Accuracy

One of the primary benefits of CNC machining is its ability to produce highly accurate and consistent parts. The machines operate based on coded instructions, which minimizes human error and allows for repeatability, even with complex designs.

2. Automation and Efficiency

CNC machining is automated, which drastically reduces labor costs and production time. Once a design is programmed, the machine can operate autonomously, often requiring minimal supervision. This leads to faster turnaround times for both prototyping and large-scale production.

3. Complex Designs and Customization

CNC machines can handle complex geometries that would be impossible to achieve manually. Additionally, they can easily produce customized parts based on specific customer requirements. This is especially useful for industries that require unique designs or low-volume production runs.

4. Reduced Human Error

Since CNC machines are automated and follow a set of programmed instructions, the chances of human error are significantly reduced. This results in higher consistency and fewer defects, which ultimately leads to cost savings.

5. Material Versatility

CNC machining is compatible with a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, wood, and composite materials. This versatility makes it suitable for industries ranging from automotive to aerospace.

6. Scalability

Whether producing a single prototype or thousands of parts, CNC machining offers scalability. The machines can handle both low and high-volume production runs, providing flexibility to manufacturers.

Applications of CNC Machining Services

CNC machining services are indispensable in a wide range of industries. Below are some key sectors that rely heavily on CNC machining:

1. Aerospace

In the aerospace industry, precision is crucial. CNC machining is used to produce lightweight and complex parts like turbine blades, structural components, and engine parts. The ability to meet tight tolerances and produce intricate designs makes CNC machining a vital tool in this field.

2. Automotive

CNC machining plays a significant role in the production of automotive components, including engine parts, transmission systems, and chassis components. It is also used in prototyping, allowing manufacturers to test new designs before mass production.

3. Medical

In the medical field, CNC machining is used to produce implants, surgical instruments, and other critical components. The high level of precision required for these parts ensures that they meet strict regulatory standards and are safe for use.

4. Electronics

CNC machining is used to create components for electronic devices, including housings, connectors, and enclosures. The accuracy of CNC machines ensures that these parts fit together properly, which is essential for the functionality of electronic devices.

5. Defense

The defense industry relies on CNC machining to create specialized parts for military vehicles, weapons, and other defense systems. These parts must adhere to strict specifications, and CNC machining offers the precision and efficiency needed to meet these demands.

6. Energy

CNC machining is used in the production of parts for energy applications, including oil and gas drilling equipment, turbines, and power generation systems. The reliability and precision of CNC-machined parts are essential in these high-stakes industries.

Choosing a CNC Machining Service Provider

When selecting a CNC machining service provider, there are several factors to consider:

1. Experience and Expertise

Look for a provider with a proven track record in delivering high-quality machined parts. Experience in your specific industry is also beneficial, as the provider will better understand your unique requirements.

2. Quality Control

Ensure the provider has robust quality control processes in place. This includes using advanced inspection tools to verify the dimensions and tolerance of parts, ensuring they meet the required standards.

3. Capacity and Scalability

Choose a provider that can handle your production volume, whether it’s low-volume prototyping or large-scale manufacturing. A flexible provider can adapt to your needs as they change over time.

4. Technology and Equipment

Modern CNC machines are more efficient and capable of handling complex tasks. Ensure the provider uses the latest technology to ensure accuracy and efficiency in production.

5. Customer Support and Communication

A reliable CNC machining service provider will communicate effectively throughout the project, providing updates and addressing any concerns promptly.

Conclusion

CNC machining services have revolutionized manufacturing by offering precise, efficient, and scalable solutions. Whether you're designing complex aerospace components, automotive parts, or medical devices, CNC machining ensures high-quality results with reduced costs and lead times. As industries continue to demand greater precision and flexibility, CNC machining will remain a key player in modern manufacturing, driving innovation and efficiency across diverse sectors.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness