Exploring China PCB Assembly: A Complete Guide to Quality and Efficiency

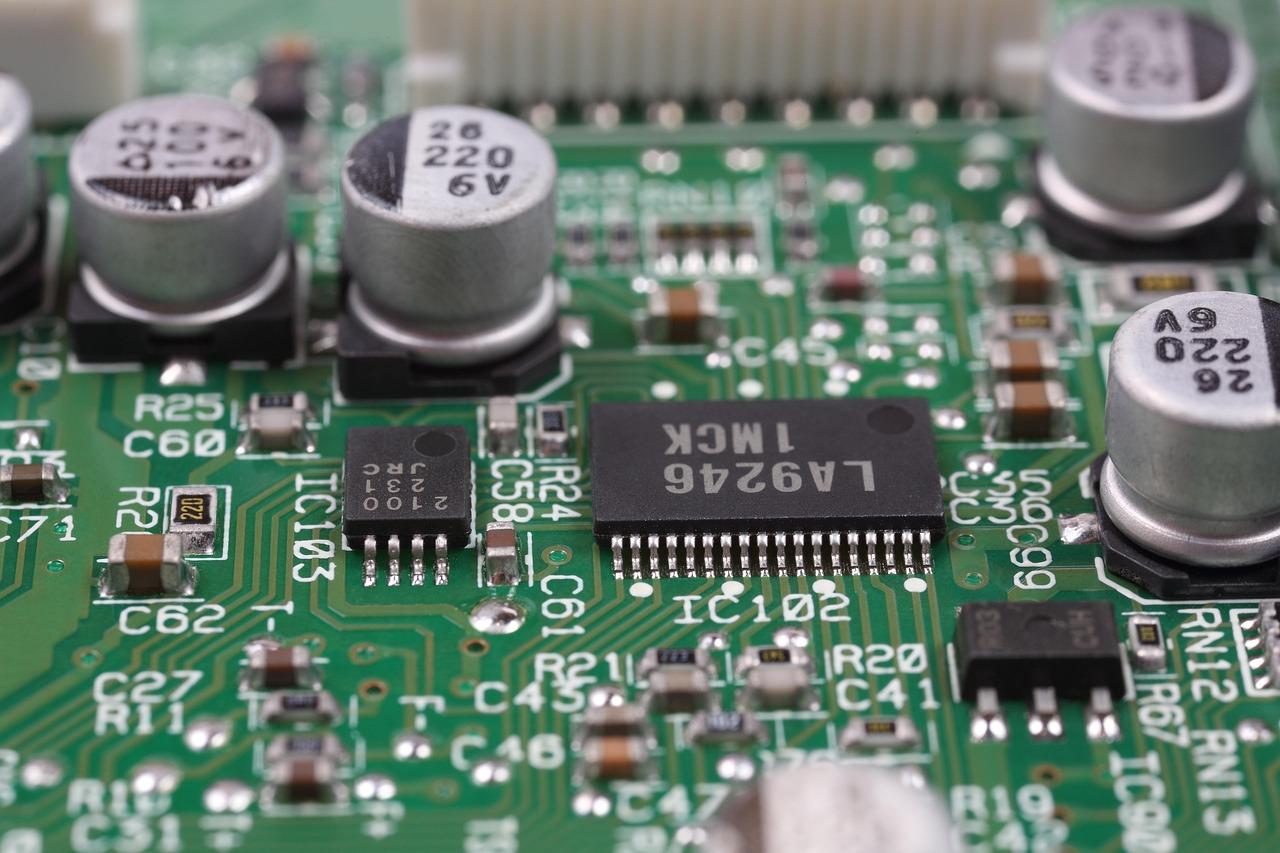

Printed Circuit Boards (PCBs) are the heart of modern electronics, driving everything from smartphones to medical devices to robotics. When it comes to PCB assembly, China has firmly established itself as a global leader, known for innovation, affordability, and fast turnaround. But how exactly has China become a pivotal center for PCB manufacturing? What should you know about the PCB assembly process in China, and how can it transform your business?

This blog unpacks the benefits, processes, and tips for navigating China PCB Assembly. Whether you're a startup creating your first prototype or a seasoned electronics company ready to scale, this guide provides the insights you need.

Why China Is a Global Leader in PCB Assembly

Expertise and Innovation

China’s reputation for PCB assembly stems from its unparalleled expertise and continuous innovation. With decades of experience, Chinese manufacturers have developed highly advanced techniques, from surface-mount technology (SMT) to through-hole assembly. They combine this expertise with cutting-edge equipment that ensures accuracy, consistency, and quality for even the most complex PCB designs.

Innovation is also a key driver. Chinese manufacturers are leaders in adopting Industry 4.0 technologies, including automation and smart production lines. This allows them to meet diverse demands, catering to industries like aerospace, automotive, consumer electronics, and healthcare.

Cost-Effectiveness

China achieves cost efficiency without sacrificing quality. Economies of scale, access to raw materials, and the high availability of skilled labor significantly reduce production costs. For businesses on tight budgets, this cost advantage can make prototyping and production far more accessible.

Fast Turnaround Times

Time is of the essence in the fast-paced world of electronics. Chinese manufacturers leverage streamlined processes, efficient supply chains, and flexible production schedules to deliver lightning-fast turnaround times.

Comprehensive Ecosystem

What sets China apart is its robust ecosystem for electronics manufacturing. From PCB design to fabrication, assembly, and testing, everything happens within an interconnected supply chain. This consolidated approach minimizes delays and simplifies logistics, enabling single-source solutions for businesses of all sizes.

The PCB Assembly Process in China

To make the most of your partnership with a Chinese PCB assembler, it’s essential to understand the key steps involved in the process.

1. PCB Fabrication

The process begins with PCB fabrication, where the physical board is created. Manufacturers use materials such as fiberglass or aluminum, adding conductive copper layers to form the circuit pathways.

2. Component Sourcing

Once the board is ready, the next step is sourcing electronic components. Chinese manufacturers often procure quality components directly from well-known suppliers or utilize their extensive inventory. They ensure that the components meet industry regulations while adhering to technical specifications outlined by the client.

3. Assembly Techniques

There are two main methods for assembling components onto PCBs:

- Surface-Mount Technology (SMT): Suitable for small, lightweight components mounted directly onto the board’s surface. SMT is fast, precise, and ideal for high-density circuit designs.

- Through-Hole Technology (THT): Components are inserted into drilled holes and soldered onto the board. THT is often preferred for large, heavy-duty components or boards requiring higher mechanical strength.

Many Chinese factories are equipped to handle both methods, often incorporating automated assembly for efficiency and accuracy.

4. Quality Testing

Quality assurance is a critical step in the assembly process. Manufacturers in China conduct rigorous testing to ensure your PCB meets design and performance standards. Common tests include:

- Functional Testing

- Automated Optical Inspection (AOI)

- X-Ray Inspection (for SMT boards)

- Environmental and reliability tests to confirm durability under specific conditions

5. Packaging and Delivery

After passing quality inspections, the assembled PCBs are carefully packaged to prevent damage during transit. With extensive logistics networks, manufacturers ensure timely delivery to locations worldwide.

Benefits of Choosing China for PCB Assembly

Advanced Scalability

China’s manufacturing framework allows businesses to seamlessly scale from prototyping to full-scale production. Whether you need 10 prototypes or 100,000 units in mass production, Chinese PCB assemblers adapt effortlessly to your needs.

Quality Assurance Measures

Top-tier Chinese manufacturers comply with international quality standards, such as ISO 9001, RoHS, and IPC guidelines. Consistent updates in their processes ensure reliable production every time.

Customization Options

Need PCBs with unique specifications or niche requirements? Chinese manufacturers offer high customization levels, enabling you to collaborate on everything from board material to layer count, size, and specialized functionalities.

Excellent Customer Support

Many reputable manufacturers provide dedicated account managers and flexible communication channels, allowing businesses to stay updated at every stage of production.

How to Choose the Right PCB Assembly Partner in China

With so many options available, how do you pick the right partner to assemble your PCBs? Here are some tips to guide your decision-making process.

Look for Certifications

Check if the manufacturer adheres to industry-standard certifications like ISO 9001, ISO 14001, or IPC-A-610. These certifications indicate stringent quality controls and ethical business practices.

Evaluate Experience

Research the manufacturer's track record. Have they worked with businesses in your industry? Are they equipped to handle complex PCB designs? Look for reviews and client testimonials to get a clear picture of their expertise.

Assess Technological Capabilities

Not all manufacturers are equal when it comes to technology. Opt for partners with advanced production equipment, automation capabilities, and Industry 4.0 integrations to ensure cutting-edge results.

Verify Testing Protocols

Thorough testing minimizes defects and ensures reliability. Your ideal PCB partner should offer a range of testing options, including functional tests, AOI, and environmental assessments.

Ask About Lead Times

Discuss timelines upfront to avoid potential delays. Reliable manufacturers offer transparent schedules and safeguard turnaround times with excess capacity and backup plans.

Consider Logistics Support

Ensure the manufacturer has solid logistics operations for dependable delivery to your location. Options for real-time tracking or international shipping expertise are a big plus.

Bringing Your Vision to Life with a Trusted Partner

Navigating the world of PCB assembly in China may seem daunting, but with the right partner, it’s an opportunity to elevate your product’s potential. From cost savings to unmatched quality, China’s PCB assembly services are designed to bring innovation, efficiency, and creativity to your doorstep.

Start small by prototyping your design and scaling as you gain confidence in the process. Explore several manufacturers—many offer consultations to walk you through possibilities tailored to your needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness