Direct Reduced Iron Market Outlook, Size, Growth, Price, Latest Trends & Industry Forecast 2032

Direct Reduced Iron (DRI) is playing a crucial role in the transition toward sustainable steel production. Produced through the direct reduction of iron ore using reducing gases such as hydrogen or natural gas, DRI offers a lower-carbon alternative to traditional blast furnace methods, which rely on coal-based coke. With the growing emphasis on decarbonizing the steel industry, DRI is gaining momentum as a preferred raw material for electric arc furnaces (EAFs), enabling steel manufacturers to reduce carbon emissions while maintaining high-quality steel production.

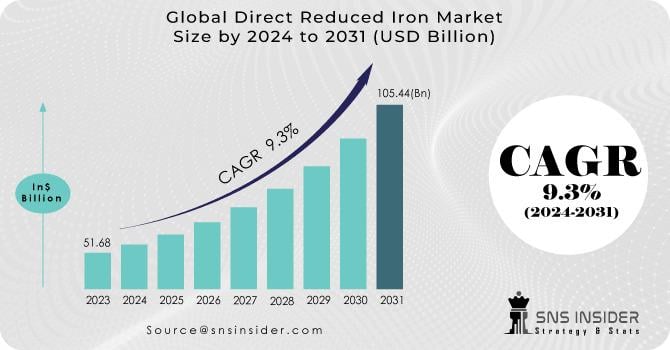

The Direct Reduced Iron Market size was USD 51.68 billion in 2023 and is expected to Reach USD 105.44 billion by 2031 and grow at a CAGR of 9.3% over the forecast period of 2024-2031.

Future Scope

The demand for DRI is expected to surge as steel producers move toward greener production methods. The adoption of hydrogen-based DRI processes is gaining traction, aligning with global carbon neutrality goals. Additionally, advancements in renewable hydrogen production will further enhance the sustainability of DRI, making it an integral part of the green steel revolution. The expansion of EAF technology and increased government support for low-carbon steelmaking are also expected to drive the growth of DRI-based steel production.

Emerging Trends

The transition from natural gas to hydrogen as a reducing agent is a significant trend in the DRI industry, reducing emissions even further. The growing use of DRI in scrap-based steel recycling is enhancing circular economy initiatives. Additionally, several steel manufacturers are investing in large-scale DRI plants to support their decarbonization strategies. Strategic partnerships between iron ore suppliers and steelmakers are ensuring a steady supply of high-quality DRI-grade iron ore, further strengthening the industry’s sustainability efforts.

Key Points

· Direct Reduced Iron (DRI) is a low-carbon alternative to traditional blast furnace-based steelmaking.

· It is primarily used in electric arc furnaces to produce high-quality steel with lower emissions.

· Hydrogen-based DRI processes are gaining momentum as industries aim for carbon neutrality.

· Investments in renewable hydrogen production are driving the sustainability of DRI-based steelmaking.

· Strategic collaborations between iron ore suppliers and steelmakers are ensuring a steady supply chain.

Conclusion

Direct Reduced Iron is revolutionizing the steel industry by offering a cleaner and more sustainable production method. As decarbonization efforts intensify, the adoption of hydrogen-based DRI and the expansion of EAF technology will continue to grow. With increasing investments and technological advancements, DRI is set to become a cornerstone of sustainable steelmaking, reducing the industry's environmental footprint while ensuring long-term viability.

Read Full Report @ https://www.snsinsider.com/reports/direct-reduced-iron-market-3005

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness